Take a look at our newest merchandise

Constructing advanced meals security methods requires just a few subsequent steps within the type of prerequisite packages (PRPs).

Operations equivalent to common cleansing and sanitation, and even correct handwashing to keep away from cross-contamination, are all a part of a much bigger meals security program. Because the time period suggests, prerequisite packages should be glad to ascertain extra advanced meals security plans such because the Hazard Evaluation Important Management Level (HACCP).

Establishing right prerequisite packages builds a strong basis for different meals security plans and reveals a agency dedication to defending public well being. These operations can considerably reduce the stress on implementing meals security plans because the hazards are already addressed within the earlier levels of the manufacturing course of.

Do you don’t have any thought which prerequisite packages apply to your meals enterprise? We made this text only for you. Learn on to study extra about PRPs and their significance to the meals trade.

Key takeaways

-

Prerequisite packages (PRPs) are foundational parts essential for constructing an efficient HACCP plan in any meals enterprise, making certain that hazards are managed early within the meals manufacturing course of.

-

These packages cowl primary meals security practices equivalent to correct handwashing, common cleansing, and sanitation, which assist stop contamination and guarantee a safer meals atmosphere.

-

PRPs are important for meals producers and retail meals shops alike, taking part in an important function in sustaining meals hygiene and security requirements.

-

Implementing right PRPs can scale back the stress on extra advanced meals security methods by addressing potential hazards early.

-

Complete coaching and data in meals hygiene are vital for meals handlers, emphasizing the significance of instructional prerequisite packages.

-

PRPs are designed to set the stage for detailed HACCP plans by establishing primary circumstances and controls that assist meals security.

-

The excellence between PRPs, OPRPs, and CCPs is vital, with PRPs offering the overall practices wanted to assist extra focused and significant meals security measures.

-

Efficient PRPs are instrumental in serving to companies meet regulatory requirements and preserve shopper belief by making certain the manufacturing of protected meals.

-

FoodDocs’ AI-powered HACCP system can shortly generate tailor-made PRPs and HACCP plans, serving to companies meet compliance necessities effectively.

What are the stipulations in meals hygiene?

Meals hygiene can solely be achieved within the meals enterprise with the fitting instruments and data of what causes foodborne sicknesses which have hostile well being results and how one can management them. It’s the duty of a meals security administration and manufacturing supervisor to supply the required circumstances and stipulations to create a hygienic working and repair atmosphere.

Listed here are just a few stipulations to attaining meals hygiene in your meals enterprise:

- Information and meals hygiene coaching. Meals handlers with direct management over service should be correctly acquainted with the importance of meals security. They should have sufficient data on how it may be achieved by way of correct meals hygiene. Satisfactory coaching on dealing with meals and holding the atmosphere clear to forestall lack of manufacturing security is a should for each meals handler.

Though within the UK, meals handlers are usually not required to have any sort of certificates, it’s the administration’s duty to supply primary coaching on how one can deal with meals. Understanding the implications together with the right operations might help meals handlers admire meals hygiene extra.

- Satisfactory management measures. Course of controls are controllable steps in your every day operations that assist preserve meals security. Management operations embrace correct cooking, storage circumstances, provide of high quality supplies, and routine upkeep of all gear. The applying of such procedures helps stop contamination from occurring.

- Correct design of amenities. The structure and design of your meals enterprise facility contribute to meals hygiene. You should make sure that the design, such because the supplies used and the structure of your institution, doesn’t entice nor acquire contamination, together with pest droppings and dirt.

This prerequisite additionally contains the presence of operational gear that assist preserve meals security, equivalent to temperature, humidity, and lighting stage controls within the processing space. One other instance could be the set up of a air flow system to forestall airborne contamination.

- Instruments and gear for cleansing. To realize correct meals hygiene, meals handlers should have the ability to carry out operations equivalent to handwashing, cleansing, and sanitizing your facility and meals contact surfaces. To do that, you should present the right instruments and gear, equivalent to a handwashing sink in addition to brushes, mops, and cloths for cleansing.

- Meals security administration system. This prerequisite features a set of systematic operations with the target of controlling contaminations and stopping them from inflicting foodborne sicknesses with extreme well being results. Essentially the most extensively famous meals security plan within the meals trade is the HACCP plan. It incorporates a complete set of data and different minor plans that assist meals handlers guarantee compliance with meals security laws. However don’t worry, in FoodDocs, you get HACCP Plan completed in 1 hour.

Earlier than finalizing a HACCP plan, your crew should make sure that your online business complies with the essential prerequisite packages (that is additionally coated in our free HACCP Plan template). Satisfying these stipulations solves probably the most primary meals questions of safety, permitting meals handlers to concentrate on extra sophisticated hazardous threats.

What’s a prerequisite program?

A prerequisite program (PRP) in meals security is a system that gives the essential circumstances to function in a protected atmosphere for the manufacturing of healthful meals. These packages may be handled as the muse of each succeeding meals security plan.

Prerequisite packages are composed of primary meals dealing with practices and manufacturing procedures that promote security and good sanitary situation. These circumstances handle primary meals questions of safety with out the necessity for advanced monitoring data.

The prerequisite packages have historically been based mostly on present Good Manufacturing Practices (cGMP) Because the meals trade grew, extra prerequisite packages have stemmed from this apply.

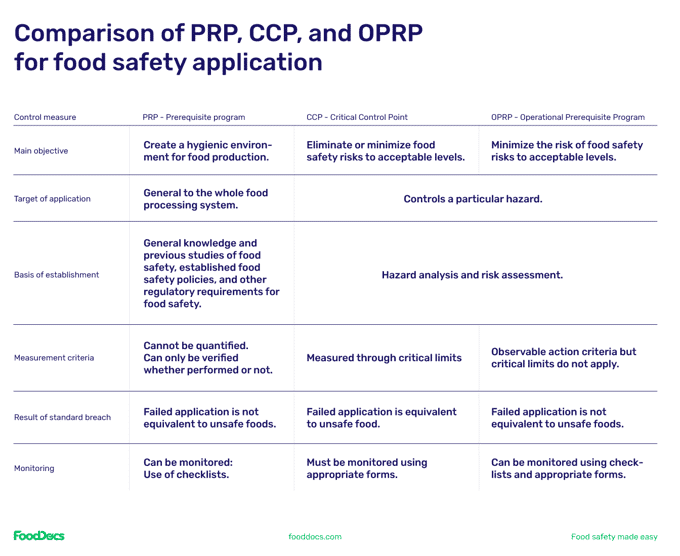

The time period prerequisite program is usually mistaken for different methods that make up a meals security plan. Phrases such because the Operational Prerequisite Program and Important Management Factors are at all times mistaken with PRPs. Regardless of this, these phrases are very totally different from one another. We encourage you to learn additional to know the distinction.

What are prerequisite packages for a HACCP program?

Prerequisite Program vs HACCP Plan

The prerequisite program is part of the HACCP Plan. Prerequisite packages are referred to as as such as a result of they should be glad first earlier than a meals enterprise can verify a HACCP plan. PRPs are preventive upkeep procedures that structure the strong basis for extra advanced plans with stringent and particular controls for meals security. Operations equivalent to pest management packages assist increased meals security plans management the potential presence of bodily and organic contaminations.

The operations underneath the PRP are preliminary steps for sustaining meals hygiene and security. However, a HACCP plan consists of different extra complete course of steps and methods that intention to regulate particular well being hazards. HACCP is a much bigger program underneath which PRPs are.

HACCP stipulations vs Operational Stipulations

HACCP prerequisite packages and operational prerequisite packages are each important for the success of a HACCP plan. The 2 classes of operations have totally different capabilities and profit a meals enterprise in a different way as nicely.

Operational prerequisite packages (OPRP) goal a selected meals security hazard. It may be monitored, however solely to an extent and with out the applying of vital limits. This implies, that monitoring procedures for OPRPs are solely restricted to a sure or no reply concerning their effectiveness.

As well as, OPRPs are usually not intrinsic in nature. Which means whereas their contribution to the manufacturing course of is necessary, eradicating them is not going to have an effect on the protection or the standard of the manufacturing. An instance could be putting in a detector for international supplies or bodily hazards. Whereas this operation acts as an exercise of verification, eradicating it for some companies is not going to considerably have an effect on the manufacturing course of.

As mentioned, PRPs are usually not designed to focus on a selected hazard with unacceptable well being dangers. They’re utilized to usually create a protected atmosphere for meals manufacturing. PRPs, in contrast to OPRPs, should at all times be current. The essential meals hygiene practices included in PRPs are required by increased meals security plans to work.

HACCP prerequisite vs Important Management Level

Important management factors are the final operation that can management a selected hazard with vital limits based mostly on regulatory requirements, whereas PRPs are normal operations that don’t require limits. The place CCPs may be operations equivalent to cooking that require limits of inner temperature, PRPs equivalent to correct hygiene are solely monitored for being correctly executed.

A vital management level is accompanied by monitoring varieties, vital limits, and complete verification procedures to comply with. However, PRPs are simply managed by way of steps equivalent to coaching and checklists. CCPs depend on correct identification of hazards and their evaluation accompanied by a organic danger evaluation. A CCP is used to regulate an recognized and analyzed hazard to acceptable ranges, whereas a PRP helps preserve all potential hazards at a minimal even earlier than they attain a CCP.

Each CCPs and PRPs require deviation data for verification actions.

PRP vs CCP vs OPRP

Who wants prerequisite packages?

Prerequisite packages are required for any kind of meals enterprise, whether or not for meals producers or retail meals shops. So long as you might be coping with healthful meals manufacturing, distribution, service, and even meals retail, you would wish to use PRPs in your meals operations. These packages embrace primary operations that assist reduce contamination of merchandise in meals service operations and meals processing crops.

A great instance of a PRP that applies to all meals companies is Good Manufacturing Practices. This PRP contains meals operations equivalent to correct private hygiene, common cleansing and sanitation procedures, meals premises structure, and correct conduct throughout working hours.

The applying of strategies in PRPs is important to making a protected working atmosphere. These sanitary circumstances are for each the meals workers and the protected meals merchandise they’re dealing with. Lack of management over the following steps of PRPs might result in questions of safety such because the contamination of merchandise with rippling results.

Examples of prerequisite packages for HACCP

A meals security plan depends on prerequisite HACCP necessities to grow to be efficient. The PRPs of a meals enterprise handle meals questions of safety and make them extra manageable for Important Management Factors.

Listed here are a few of the most typical prerequisite packages used within the meals trade:

Word that each one these are answerable for totally different areas of meals security and subsequently complement one another.

Packages can also contain management of meals security in receiving incoming supplies, water methods, laboratory checks, and different areas that contribute to the protection of your completed merchandise. Whereas these packages don’t require vital limits, they’re important in holding the environmental circumstances protected for the manufacturing of meals for consumption.

Accountable meals enterprise operators should be acquainted with all customary working process paperwork associated to their duties for efficient software. That is to assist them carry out all PRPs appropriately on a regular basis.

HACCP prerequisite program guidelines

Relying on the character of your meals enterprise operations, there are prerequisite packages that can contribute considerably to meals security.

Checklist of prerequisite packages for HACCP

Undecided which areas want prerequisite packages? Here’s a quick HACCP prerequisite program guidelines for meals institutions:

- Gear calibration procedures

- Efficient upkeep program

- Cleansing and sanitation program

- Water security procedures/ Water remedy procedures

- Construction and structure of the power

- Waste administration

- Pest management actions

- Personnel hygiene and worker well being

- Meals security employees coaching

- Uncooked materials manufacturing and receiving (contains temperature management)

- Format zoning

- Provider management

- Inventory management

- Recall and traceability

- Allergen management program

- Audits and inspections

- Product labelling and packaging supplies

Every PRP should have an entire set of directions on how they are often carried out, the personnel concerned, and acceptable corrective actions for deviations when relevant. The operational data established for PRPs should at all times be accessible to all meals enterprise operators, particularly these answerable for the operation.

How you can set stipulations for HACCP

Stipulations are set in a meals institution by making detailed documentation. These correct data embrace directions on how one can carry out the PRPs and the concerned personnel in every operation. These paperwork will then be used to instruct workers and as a reference in case of non-compliance.

In making a HACCP prerequisite program, customary working procedures should comprise the next info:

- Process title

- Description and rationale of the prerequisite operation

- People answerable for the operation with the titles of personnel

- Conditions the place the operation is relevant

- Process on how one can carry out the operation

- How usually ought to the operation be carried out

- Monitoring frequency and procedures to make sure that meals handlers appropriately carried out the operation

- Verification procedures

- Corrective actions in case of non-compliance

Creating customary working procedures for every PRP may be time-consuming. Not to mention, they should be at all times versatile to accommodate adjustments and enhancements, particularly after a meals security audit.

How can FoodDocs assist create prerequisite packages?

Prerequisite packages are important for a enterprise within the meals chain of manufacturing. Whereas some international locations don’t require stringent meals security methods, PRPs are the minimal regulatory requirements and the important basis for producing protected meals merchandise.

Fortunately at FoodDocs, we might help you generate all the required prerequisite packages and a customizable HACCP plan template in simply 1 hour. Powered by synthetic intelligence, our system can generate probably the most relevant PRP paperwork in your meals institution.

Our system will generate PRPs full with the next info:

- PRP Title

- Description and rationale of PRP

- Preventive procedures

- Monitoring exercise and personnel accountable

- Corrective actions

Whenever you use our digital resolution, you will get PRPs for the next operations:

1. Meals dealing with atmosphere. Contains preventive measures equivalent to primary worker practices in dealing with meals and operations that create a protected working atmosphere.

2. Upkeep of atmosphere and gadgets. Prevents sudden gear failure by way of common upkeep and calibration procedures and ensures that each piece of apparatus is working.

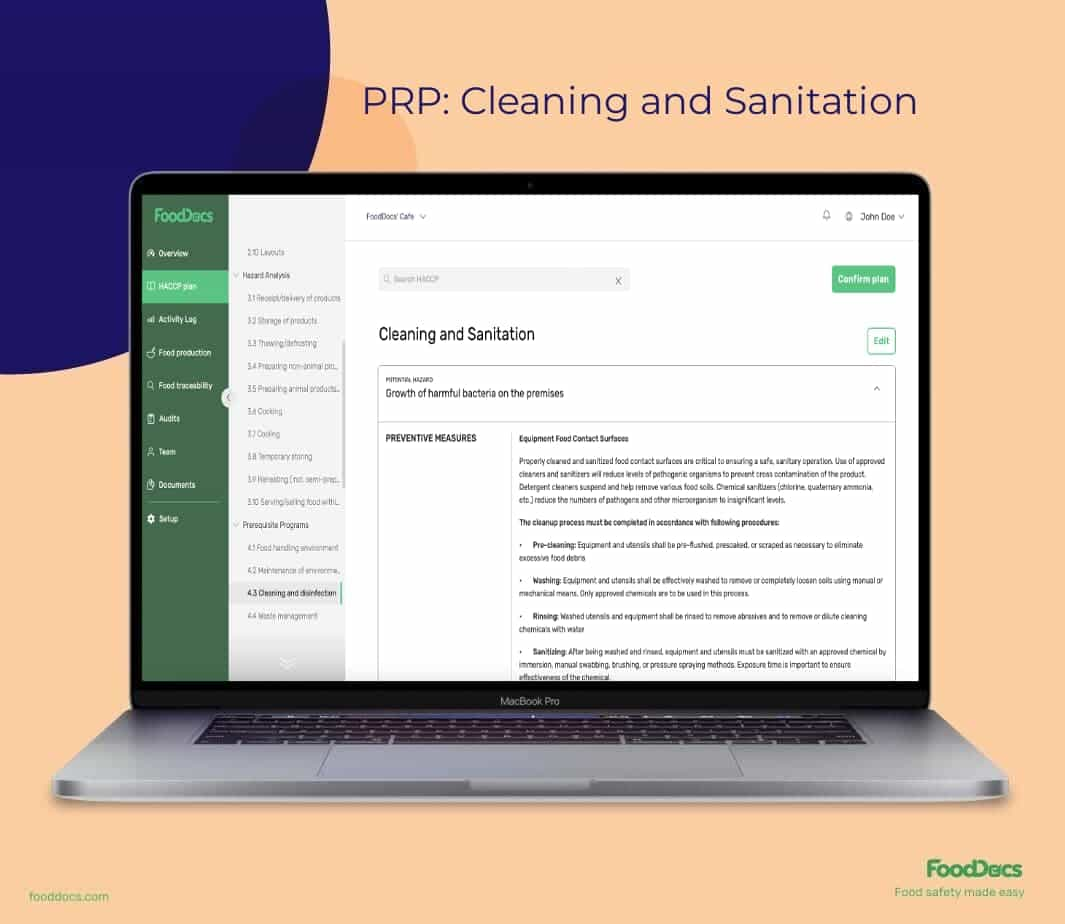

3. Cleansing and sanitation. Contains meals operations for cleansing all areas and meals surfaces that are available in contact with meals merchandise in your institution. This part additionally has preventive measures in opposition to chemical contamination of product from non-food chemical compounds.

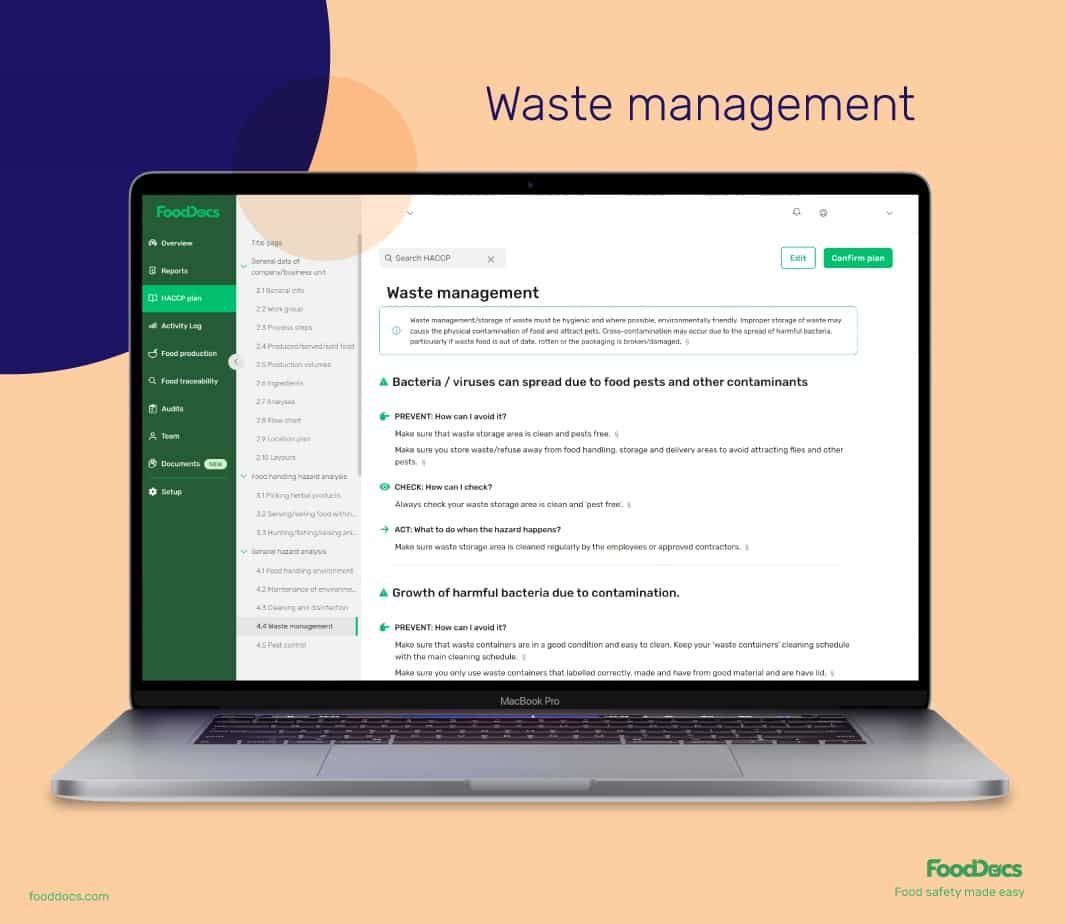

4. Waste administration. Set of operations to create a clear working atmosphere free from meals waste merchandise and potential organic hazards that will come from them.

5. Pest Management Program. Contains meals operations that assist management the presence of pests in addition to operations to forestall cross-contamination from the options used to remove pests.

6. Meals contamination. A program that encompasses preventive controls for chemical, organic, and bodily contaminations, equivalent to enough separation of instruments to forestall cross-contamination.

7. Laboratory analyses, water management. A program used to forestall the unfold of microbiological hazards that will come from contaminated water and its use everywhere in the meals institution.

8. Allergens and shopper info. Protocols for dealing with allergenic and non-allergenic foodstuff.

9. Personnel hygiene, medical situation and coaching. Comprises directives and customary procedures for meals enterprise operators when getting ready meals, in addition to how workers with hostile well being circumstances can have an effect on meals security.

10. Number of suppliers and uncooked supplies. This program contains operations wanted for choosing suppliers and the protection and high quality management operations used to judge the uncooked supplies they supply.

11. Temperature and shelf-life management. Contains preventative measures for controlling the situation of storage between packaging and supply (e.g., storage temperature and humidity) in addition to for dealing with meals which have gone previous their expiration dates.

12. Buyer complaints and withdrawal/recalling of unsafe meals. A complete correct management measure on how one can deal with complaints from clients and potential remembers minimizing meals questions of safety.

Our digital resolution can save your crew a major period of time that you just in any other case must spend on crafting these PRPs. With our resolution, you may focus simply on customizing the HACCP plan that we will mechanically generate for you.

Along with PRPs, our software program can generate a customizable, digital HACCP plan template full with all of the important sections of a HACCP plan. You may get a meals security plan with the next parts:

- Established hazard identification and evaluation

- Established vital management factors

- Important limits

- CCP monitoring procedures

- Corrective actions

- Verification procedures

- Document-keeping and documentation procedures.

Our digital resolution might help you get your HACCP plan with detailed PRPs completed 500x sooner than hiring a meals security advisor or doing all your plan the standard manner.