Try our newest merchandise

Improve your consciousness of organic, chemical, and physical-related important management factors.

One of many trickiest elements of constructing a HACCP meals security program is that no two companies are comparable and the identical situation applies with important management level examples. Vital management factors can differ from one meals product to a different even when they’re from the identical enterprise.

Regardless of this, realizing the primary ideas of most CCPs in a meals security plan provides you a stable basis on the way to simply establish which of them are relevant to your enterprise.

Key takeaways

- Vital management factors (CCPs) are important in eliminating, stopping, or decreasing hazards to an appropriate stage within the meals provide chain.

- The CCP determination tree aids in figuring out whether or not particular meals processing steps must be thought-about CCPs by answering a sequence of questions.

- Thermal cooking processes are designed to focus on microbiological pathogens and are sometimes thought-about CCPs once they meet particular temperature and time necessities.

- Chilly storage should be maintained at particular temperatures (40°F for chillers and 0°F for freezers) to manage organic hazards and forestall enzymatic degradation.

- Scorching holding guidelines state that high-risk meals should not be within the temperature hazard zone between 40°F and 140°F for greater than 4 hours to forestall pathogen progress.

- Product formulation together with acidulants and preservatives performs a important position in stopping microbial progress and guaranteeing meals security.

- Packaging supplies should be appropriate to forestall chemical hazards equivalent to corrosion in canned meals and contamination from meals processing gear.

- Bodily contaminations like steel, glass, or organic hazards from bugs and rodents will be managed by means of rigorous inspection and correct hygiene practices.

- Failure to manage a CCP can result in hazardous meals, necessitating instant corrective actions and reevaluation of the meals security plan.

- FoodDocs’ digital meals security administration software program makes use of machine studying to establish and counsel CCPs, considerably decreasing the time wanted to create HACCP plans and guaranteeing compliance with laws.

What’s a important management level?

Vital management factors are any strategies within the meals processing line that may eradicate, forestall, or cut back any perceived potential hazard to an appropriate stage. The significance of appropriately figuring out CCPs can’t be overstated for the sake of meals security.

These processes are vital elements of your complete meals chain provide that ensures serving solely protected meals merchandise to your clients. Regulatory businesses within the meals business have established primary and normal CCPs from which you’ll select and apply to your meals enterprise. Though, choosing out which one is greatest for you could be a bit complicated.

How you can establish a important management level

Typically workers ask whether or not handwashing or cleansing will be CCPs. In most HACCP programs, these are thought-about prerequisite packages (PRPs), not CCPs.

Nonetheless, if a cleansing step is the ultimate barrier to manage a hazard, it could be handled as a CCP. For instance, verifying the sanitation of kit earlier than switching from an allergen-containing product to an allergen-free one.

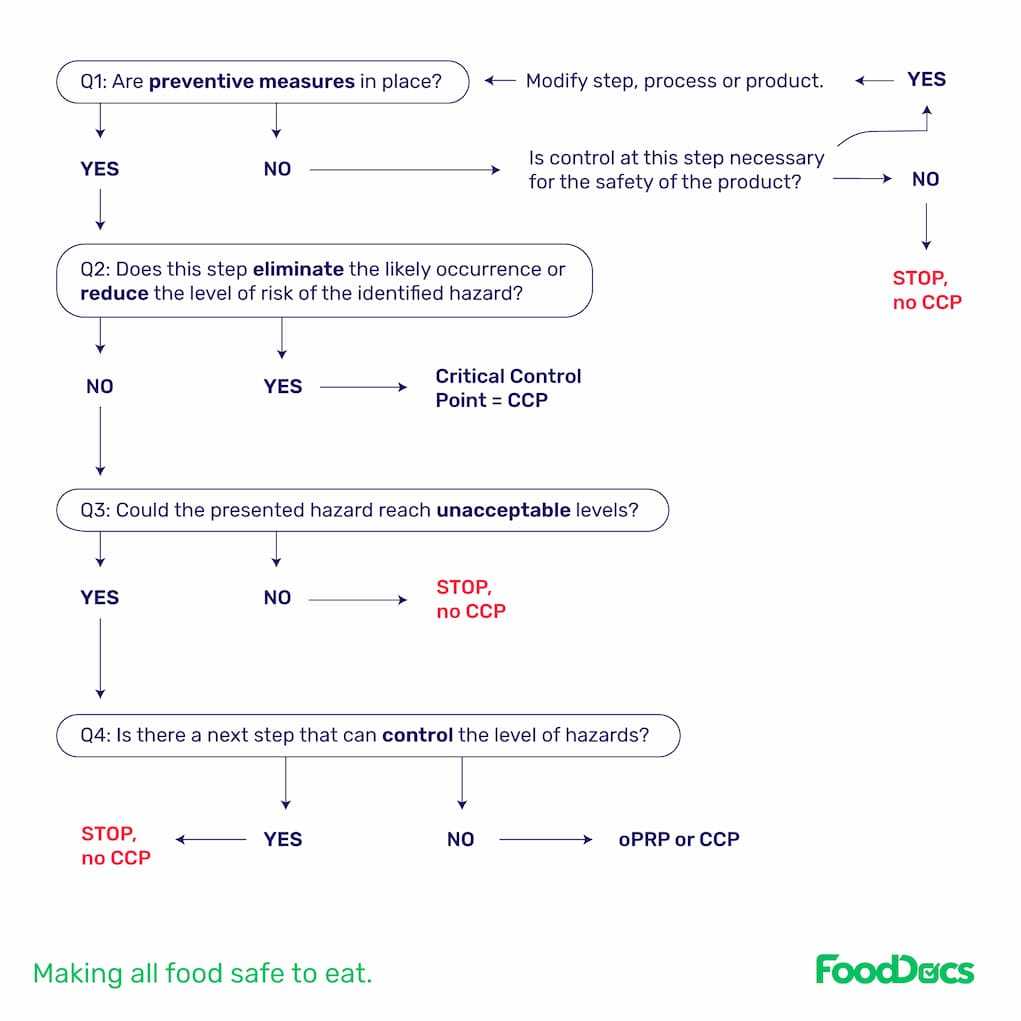

Use a CCP determination tree to assist make clear which step qualifies. A CCP should forestall, eradicate, or cut back a particular hazard to a protected stage.

Desk of CCP examples by hazard kind

Here’s a fast reference information to widespread CCPs throughout completely different hazard sorts that may assist simplify CCP identification based mostly on the kind of hazard your course of is most in danger for:

| Hazard kind | Instance CCPs |

|---|---|

| Organic | Cooking to 165°F (74°C), fast chilling, chilly holding under 40°F |

| Chemical | Appropriate acidification to pH 4.6, verifying cleansing brokers are rinsed off surfaces |

| Bodily | Steel detection, sieve inspection, packaging checks for glass or plastic items |

| Allergenic | Allergen-free gear verification, label checks, ingredient separation |

What are the commonest important management factors?

Most important management level examples of a primary HACCP meals security plan are made for the containment, prevention, or elimination of microbiological hazards. The presence of microbiological pathogens is taken into account as a major contributing issue to meals questions of safety equivalent to any foodborne sickness.

Regardless of this, that doesn’t imply that there aren’t any important management factors associated to chemical and bodily hazards. Beneath are some CCP examples for every kind of hazard.

Organic hazard testing

Cooking (Thermal processing)

Maybe the commonest technique of eradicating organic hazards is thru making use of numerous cooking strategies to your meals product at a particular meals temperature. Most thermal cooking processes are designed to focus on a microbiological pathogen that’s recognized to infect or inherently reside in a product.

Time and temperature combos are established based mostly on the sensitivity of the microorganism whereas, in fact, conserving the standard of the product healthful.

The presence of thermal cooking strategies doesn’t essentially imply that they’re important management factors. An instance of that is in baking. Thermal processing is utilized to the dough to bake it into bread and never primarily due to meals questions of safety. Vital management factors are steps which might be used to eradicate hazards that may trigger hazard to public well being.

An excellent instance of thermal processing that may be thought-about as a important management level can be cooking meat to a required inside temperature.

Whether or not it’s rooster, beef, or pork you’re coping with, the proper inside temperature for cooking these proteins has been established and applies to most nations. Particularly for rooster, the thermal cooking CCP is established as cooking the poultry meat to a minimum of 165°F and relies on the 5-log discount kill step of the pathogen Salmonella.

As well as, contemplating a thermal course of step as a CCP would additionally rely on the character of your meals enterprise. When you’re coping with beef at a dine-in restaurant, thermal processing will be disregarded as a CCP if the shopper needs it to be cooked as uncommon and the meals will probably be eaten instantly.

This isn’t the case when producing ready-to-eat beef merchandise. The required inside temperature should be achieved to increase the shelf-life of your meals product. Storing a slice of beef cooked uncommon will spoil quicker than when cooked well-done even when they’re each refrigerated.

Low-temperature storage

To regulate the expansion of many microbiological pathogens, low-temperature or chilly storage is likely one of the greatest important management level examples. In response to the FDA, to manage organic hazards from occurring, your chiller should be saved at 40°F and your freezer at 0°F (4°C and -18°C, respectively).

Regulatory normal working procedures for the transportation of meals in chilly storage can be found in several nations. An instance can be the ATP Settlement by nearly 20 nations and is entitled as “Settlement on the Worldwide Carriage of Perishable Foodstuffs and on the Particular Gear to be Used for Such Carriage.”

Beneath this settlement, frozen and chilled meals equivalent to meats and dairy merchandise are topic to complete regulatory temperature controls.

Throughout chilly storage, microbiological actions should not the one processes prevented but additionally enzymatic degradation. Beneath very low temperatures, enzyme actions equivalent to browning, oxidation, and protein breakdown are stopped. Failure to maintain perishable meals at persistently low temperatures invitations meals security dangers.

If your enterprise is in step with supplying uncooked meats within the meals business, you’ll certainly be required to have temperature management on your transport and storage. Equally, vegetable and fruit produce require cool temperatures to maintain them contemporary throughout transport.

We provide a handy approach of constructing your personal temperature monitoring log and an easy-to-edit temperature chart template at FoodDocs on your numerous merchandise that you would be able to obtain free of charge.

Excessive-temperature storage (sizzling holding)

For any sizzling meals that requires high-temperature holding equivalent to for soups in cafeterias or a number of meals merchandise in a buffet set-up, a normal rule of 2 hour/4 hour is utilized. This rule states the utmost time that doubtlessly high-risk meals can keep inside the hazard zone.

The temperature hazard zone is anyplace between 40°F and 140°F (5°C and 60°C, respectively). This vary is the place most pathogens optimally develop. As such, meals meant to be served for an extended time in ambient temperatures should be held at greater temperatures.

Beneath the beforehand talked about rule, meals equivalent to meat or these containing meat, dairy, and associated merchandise, starchy meals equivalent to rice and pasta, cooked greens and a few fruits, and egg merchandise can solely be held on the indicated time inside the hazard zone.

That’s, the talked about examples can solely be safely consumed or used for a most of 4 hours and optimally as much as 2 hours solely. Past this indicted time, meals should not be consumed and thrown away instantly.

Cooling

The primary level of cooling cooked meals quick is for its temperature to not keep too lengthy within the temperature hazard zone. For companies that require superior meals preparation equivalent to for some operations in meals catering providers, merchandise should be cooled to a temperature of 70°F inside 2 hours.

At this level, the meals will be refrigerated and should not keep longer in ambient circumstances if the meals is supposed to be served afterward. Speedy cooling with out the danger of cross-contamination prevents pathogens from recovering from the thermal processing that was utilized.

Product formulation

We all know how your product growth crew has spent so many hours to provide you with the product you will have now or how nice your loved ones’s recipe is that you simply began a enterprise round it. No matter the way you constructed your product, a few of its substances play a important position in sustaining meals security.

Secure product formulation accommodates a whole lot of important management examples particularly in terms of preservatives, each pure and synthetic. One of many widespread important management factors associated to formulation is the addition of an acidulant which will be vinegar, citric acid which comes from lemon or different acidic fruits, and lactic acid.

Acidulants cease the expansion of most microbial pathogens recognized to trigger sure foodborne sicknesses such because the Staphylococcus aureus in ready meals and Clostridium botulinum in canned meals. These pathogens can’t survive in meals circumstances which have very excessive acidity.

Elimination or failure to attain the proper acidity can encourage these pathogens to develop and trigger ailments. If your enterprise is said to pickling, comparable ideas apply to you.

Earlier than the acidification course of, some greens are soaked in brine options to cut back water exercise and take away preexisting pathogenic microorganisms. This can be a important step for the success of fermentation.

Chemical hazard testing

Cooking

Research have proven that thermal processing reduces some chemical contaminants in meals. One examine aimed as an instance the way to management chemical hazards in meals as a type of establishing important management factors.

The outcomes of the examine confirmed that adequately cooking beef patties reduces the variety of polychlorinated dibenzodioxin ranges that are widespread contaminants that may be thought-about poisonous when ingested at excessive ranges.

In distinction to this management, thermal processing strategies should even be regulated as a result of extreme processing can produce contaminants together with fragrant hydrocarbons and N-nitroso compounds equivalent to acrylamide in meats.

Such contaminants are recognized carcinogens to people and can’t be eliminated after cooking. Detection if ranges have exceeded the allowable restrict by regulatory businesses can solely be carried out by means of chemical testing.

Addition of components

Testing and assurance of additive efficiency for processed meals is equally essential as with cooking. Components are utilized to meals to make sure that they will final till the claimed shelf-life. When the standard of those components is questionable, they could put the security of processed meals in danger, and due to this fact the well being of shoppers.

An instance of that is within the manufacture of juices in PET bottles. Most juices are acidic in nature and due to this fact will forestall the expansion of micro organism, however not molds. The safety measure often carried out to deal with this potential hazard is prewashing the PET bottles with sodium benzoate answer.

This additive is barely efficient when the product is acidic. Though, warning must be practiced as a result of this additive is regulated in some nations as it may well trigger allergic reactions to susceptible shoppers.

At FoodDocs, we take these provisions and variations in laws under consideration when suggesting important management level examples to you.

Packaging

In keeping with the peace of mind of fine provides, meals packaging supplies should even be inspected. When it comes to chemical hazards, some packaging supplies could also be unsuitable on your merchandise.

An instance can be for canning acidic meals. The very low pH of such processed meals could cause corrosion when the unsuitable kind of cans are used.

Assurance of unpolluted amenities can also be thought-about one of many important management level examples. Packaging supplies can turn out to be contaminated with chemical substances from the meals processing gear and environmental contamination.

Bodily Hazard testing

Inspection

Throughout uncooked materials receiving, it’s your meals security supervisor and high quality assurance crew’s activity to make sure that the substances you obtain are free from vital contaminations.

In some large corporations equivalent to these mass-producing meals merchandise, the essential important management level instance of inspection is oftentimes offered as an computerized indicator equivalent to a steel detector. Not everybody can buy such gear and this technique would solely apply to steel items.

Different bodily contaminations will be noticed as mirror shards, hair, and bug and rodent elements. In instances of smaller-scale meals manufacturing processes, preinspection of uncooked supplies earlier than use will be thought-about as a important management level.

As soon as cooked or processed, there isn’t a different approach so that you can detect if there are any current bodily contaminants. Along with preinspection, correct hygiene and sporting of the prescribed kitchen or manufacturing protecting uniforms will be thought-about important management level examples.

In actuality, bodily contaminants convey extra than simply the potential to injure shoppers. Most bodily contaminations are additionally precursors of organic hazards. An excellent instance can be the presence of rodent hairs or insect elements. These filths are thought-about unsanitary and might carry numerous pathogenic microorganisms. This then turns into a meals security hazard.

Storage and transport

This instance of CCP is commonly missed. Throughout the storage of uncooked supplies and transport of merchandise, they’re in some way prone to break equivalent to punctures, cross-contamination, rodent bites, and others.

Most points come up because of poor sanitary practices in addition to improper storage. As soon as a completed product is compromised, there may be not a lot you are able to do since there aren’t any different succeeding steps other than distribution.

A HACCP meals security administration is extra involved with the in-line meals dealing with course of and due to this fact doesn’t often have any end-product testing. This CCP applies to nearly all meals processing facility companies.

Along with the examples already listed, some CCPs will be discovered even earlier within the meals circulation. As an example:

These steps are sometimes handled as conditions however can turn out to be important management factors in higher-risk operations or when they’re the final alternative to manage a hazard.

What are the important management factors for allergen administration?

Allergens are a number one explanation for meals remembers and buyer complaints. For a lot of companies, controlling allergens is simply as essential as stopping bacterial progress.

Listed here are examples of CCPs centered on allergen hazards:

- Ingredient verification: Confirming allergen declarations on incoming items match product specs.

- Devoted storage: Separating allergenic substances like nuts or dairy from allergen-free gadgets. (Get our free correct meals storage chart on your kitchen.)

- Gear changeover: Cleansing and verifying utensils or prep surfaces between allergen-containing and allergen-free product runs.

- Packaging and labelling: Guaranteeing appropriate allergen info is included on meals labels.

Even hint quantities of an allergen could cause severe reactions. These management factors assist forestall unintended publicity and shield each clients and your enterprise.

What’s a CCP determination tree, and the way can it assist you?

Even if you’re a long-time participant within the meals business, it may well generally be onerous to establish which processing technique will be thought-about a important management level. Most particularly, important management factors can differ from one product to the opposite. There are a number of methods to make this activity simpler for you.

At FoodDocs, we can assist you routinely counsel potential CCPs for your enterprise. Our good software program bases its recommendations on completely different precise meals dealing with enterprise knowledge and experiences. It might probably give you stable important management level examples match for your enterprise based mostly on comparatively comparable providers within the meals business.

When you resolve to do CCP identification the normal approach, the FDA has prompt the usage of a CCP determination tree. This instrument helps you resolve which amongst your processing steps is taken into account a CCP after figuring out the potential hazards in your meals manufacturing course of by presenting a circulation chart with questions which might be answerable by a Sure or a No.

For example, take into account marinating and roasting uncooked rooster breast as two strategies in your meals dealing with course of to be evaluated if they are often thought-about as CCPs for the prevention of organic hazards.

-

Are preventive measures in place?

Step one to figuring out if a processing level is a CCP is to ask “are there preventive and management measures on this step or if there are any subsequent steps that may forestall the hazard from breaching the appropriate stage?”

Taking marination into consideration, this step is usually carried out to enhance the flavour of the rooster. Nonetheless, it may well additionally reduce the extent of inherent microorganisms within the uncooked rooster breast due to its salinity or acidity, relying on the kind of marinade.

Marination comes earlier than roasting and the reply to the offered query of whether or not there’s a subsequent step to eradicate the hazard is Sure. Then again, roasting is a last step to attaining the required inside temperature of a rooster and is often the final meals manufacturing course of earlier than serving.

Because of this there aren’t any subsequent steps to deal with the organic hazard. At this level, each strategies fulfill the primary query with the reply Sure.

-

Does this step eradicate the possible prevalence or cut back the extent of threat of the recognized hazard?

On this stage of the CCP determination tree, you’re requested to find out if the step at hand is important to convey the hazard right down to acceptable ranges or utterly eradicate it. Roasting your rooster previous to serving satisfies this query and due to this fact it may be thought-about as a important management level.

Then again, marination can solely reduce the microbial load of your uncooked rooster breast on the floor stage and never internally. Marination can’t convey the extent of microorganisms inside the rooster to acceptable ranges. As such, the step wants additional analysis.

-

Might the offered hazard attain unacceptable ranges?

The third stage of a CCP determination tree evaluates the probability of the recognized hazard from occurring in extreme quantities. Salmonella and different enteric pathogens are most related to foodborne sicknesses originating from consuming inadequately cooked rooster.

When left unprocessed, their ranges can enhance to harmful ranges and create unsafe meals. As such, a safety measure is required to take care of management of meals security, and the reply to the query is Sure.

-

Is there a subsequent step that may management the extent of hazards?

The final query goals to establish if there’s a stronger manufacturing step by way of controlling the meals security hazard. As talked about beforehand, roasting can management the extent of microorganisms after marination by means of thermal cooking.

For the reason that reply to this query is Sure, marination will not be thought-about as a CCP. If in case the reply to this query is No, the step should be additional evaluated and the entire processing line should be assessed whether or not it’s match for the manufacturing of protected and healthful meals merchandise.

What occurs in the event you do not meet CCP requirements?

Controlling a important management level is as essential as figuring out them. After figuring out which manufacturing phases are important management factors, your HACCP crew is required to set important limits. These limits are the minimal and most values at which you’ll take into account that the hazard is inside acceptable ranges. The subsequent query is “What occurs in the event you do not meet these requirements and lack of management happens?”

As a meals dealing with enterprise proprietor, you need to at all times keep in mind that non-compliance to your set CCP requirements implies that a meals security hazard is current and your product is taken into account a hazardous meals.

When a important management level will not be met, a meals handler should first reevaluate the situation and apply corrective actions to deal with the lack of management. This step goals to establish at which level of the CCP did the error happen and produce again the hazard stage inside the usual.

Along with making use of corrective measures, your crew should be ready with monitoring procedures and verification varieties to find out whether or not the hazard is managed or not.

Monitoring and verification procedures will function documentation and proof for any attainable issues with the affected merchandise. Correct data are additionally offered to auditing our bodies and authorities businesses as proof that your HACCP meals security plan is efficient and environment friendly working.

Digital meals security administration and figuring out CCPs

Identification of CCPs in your manufacturing line will be a lot simpler with the assistance of our HACCP meals security plan builder. At FoodDocs, we now have developed a built-in software program that may assist you create your personal HACCP plan in simply 1 hour.

Our HACCP meals security plan builder can routinely counsel important management factors match on your complete course of. These recommendations are based mostly on a wise machine-learning program. We use this software program to routinely full essentially the most troublesome elements of your HACCP plan.

These elements embody your circulation diagram, mapping any potential hazard and important management factors, composing hazard evaluation, and setting record-keeping and documentation procedures to important limits – all important for the peace of mind of meals security.

This growth can reduce you the time you must spend on utilizing a call tree for the institution of procedures to be thought-about as important management factors. Utilizing our HACCP builder means you get to save as much as 120 hours of labor which you’ll then spend on different duties on your meals enterprise.

You don’t even have to fret whether or not these important management level recommendations are the fitting ones on your meals processing plant and if they’re compliant with the laws and legal guidelines of your location.

We tailor all facets of your HACCP plan to your meals dealing with enterprise by asking you to reply a sequence of questions associated to your meals operation.

Utilizing our providers tops discussing with a meals security guide and constructing a stable HACCP crew. You additionally get to spend 500x much less cash than what you may be spending in the event you resolve to construct your HACCP meals security packages the normal approach.

Continuously requested questions on important management level examples