Take a look at our newest merchandise

A CCP is a step in your course of the place a management measure with clear crucial limits is required to regulate a hazard.

Whenever you got down to begin a meals enterprise, you may need heard the significance of a meals security plan and figuring out all crucial management factors, however have you learnt the significance of this stuff?

As a meals dealing with enterprise, you’re liable for many issues, together with the emotional expertise of a scrumptious meal, attracting clients with a flexible menu, and producing healthful meals for consumption.

To run a protected and profitable meals enterprise, all necessities round meals security should be met to forestall the incidence of any foodborne sickness or any antagonistic well being results because of serving hazardous meals.

Key takeaways

- A Important Management Level (CCP) is a step within the manufacturing course of the place meals security hazards might be prevented, eradicated, or decreased to protected ranges.

- CCPs are important for controlling meals security dangers and making certain public well being.

- Identification of CCPs is a basic a part of a HACCP (Hazard Evaluation Important Management Level) plan, which systematically addresses potential hazards in meals manufacturing.

- CCPs could embody steps like cooking, cooling, packaging, and chemical testing to regulate numerous hazards.

- Efficient CCP administration requires exact monitoring and documentation to make sure compliance with meals security requirements.

- Management measures at CCPs differ based mostly on meals kind, processing strategies, and the particular hazards recognized.

- Common updates and strict adherence to CCP pointers assist forestall foodborne sicknesses and improve the standard of meals merchandise.

- Understanding and implementing CCPs helps meals companies keep a good fame and guarantee buyer security.

- FoodDocs presents instruments to help companies in creating, implementing, and managing their HACCP plans successfully, together with digital monitoring and alert programs.

The preliminary steps to making sure meals security are to conduct a hazard evaluation and decide any crucial management level in your complete meals chain.

Figuring out the potential hazards inside your meals dealing with course of (ordering meals, receiving meals, storing meals, and so forth.) is vital to find out at which steps these meals security dangers are most probably to happen. To deal with these hazards and produce protected meals, crucial management factors alongside the manufacturing course of are set.

On this article, we shall be diving into the significance of crucial management factors and their contribution to a HACCP meals security plan.

What’s a CCP?

In response to the FDA, a crucial management level is any course of step the place management might be utilized for the prevention or elimination of any potential meals security hazard. A scientific method and important focus are being positioned on a crucial management level alongside your meals manufacturing course of. A breach or lack of management of the established parameters for this crucial management level could cause antagonistic public well being points because of unsafe meals.

The principle prerequisite for assigning a crucial management level based mostly on the 7 HACCP ideas is to determine the potential meals hazards in every step. Meals handlers are required to handle all potential hazards which can be moderately more likely to trigger sickness or damage if left uncontrolled. These hazards could embody microbiological contamination, chemical contamination, or the presence of filth.

Examples of CCPs could embody:

- thermal course of,

- chilling,

- chemical testing

- organic hazard detection

- formulation management,

- testing any meals merchandise for any bodily hazard.

It is advisable fastidiously develop and doc all of your crucial management factors. A key objective of precisely established CCPs is to function foundations for controlling meals security hazards. An correct report of established CCPs can also be one of many 7 HACCP ideas and is important for establishing a meals security administration system when compiling your HACCP meals security applications.

It might be a bit complicated in case you are new to those phrases. Consider it this manner, a crucial management level is a step that if you neglect to do, skip, or don’t fulfill, would finally lead to lawsuits due to meals issues of safety. It doesn’t get any clearer than that. Finish-product testing doesn’t require any crucial management level since not a lot might be carried out if the meals product has already been processed.

A crucial management level is taken into account a management measure and varies relying on the character of your meals manufacturing enterprise, the kind of meals merchandise you provide, and even the uncooked supplies you employ. An ideal instance of various crucial management factors per product is the measurement of inside temperature when cooking hen or beef and storing greens.

To make hen protected for consumption and take away the chance of Salmonellosis, your uncooked hen should be cooked at round 165°F (75°C), whereas a slab of beef for roasting would solely want 145°F (round 60°C-65°C).

Think about this situation in a restaurant kitchen:

Cooking hen to the required inside temperature is a CCP as a result of undercooking may depart pathogens alive. If a chef forgets this step or miscalibrates the thermometer, the CCP failure may result in Salmonella an infection. That’s why monitoring and strict corrective motion (like persevering with to prepare dinner till temp is reached or discarding the batch) is crucial.

On one other observe, upkeep of elevated temperatures might not be relevant for meals providers that take care of contemporary produce similar to greens. Important management factors for such companies could also be chemical testing for pesticide residue or the presence of microbial toxins, and others.

Study extra about what crucial management factors don’t embody.

What are management measures?

A management measure is an motion or an exercise that may reduce or remove an recognized potential hazard or scale back its chance of incidence to a suitable stage. In different phrases, a management measure is any motion, step, process, course of, or process supposed to handle a meals security hazard. The time period management measure is used as a result of not all hazards might be prevented, however all of them might be successfully managed.

Management measures aren’t essentially thought of crucial management factors. They are often easy steps similar to correct hygiene, ample testing, sanitation routines, pest management, or common coaching.

The first step to understanding a crucial management level in meals preparation is figuring out that management measures are categorized based on their nature, relationship to the method, and the extent of threat to the patron ought to the measure fail.

Examples of management measures embody:

• Management Factors (CP)

• Important Management Level (CCP)

• Prerequisite Applications (PRP)

• Operational Prerequisite Applications (oPRP)

• High quality Management Factors (QCP)

The duty for meals security is a key component in sustaining fame within the meals business. This responsibility contains identification of hazards, the institution, and monitoring of CCPs, and making use of verification steps to make sure management of meals security. These little steps from buying substances to plating the meals that helps scale back the chance of any well being hazard and maintain your clients returning to their favourite level of deliciousness.

What are the variations between CP, CCP, PRP, and oPRP?

In a HACCP meals security plan, different terminologies similar to management level, prerequisite applications, and operational prerequisite applications could come up. To type out any doable confusion surrounding these phrases, let’s look into 4 foremost phrases that you’ll come throughout when figuring out management measures and any crucial management factors for meals security.

Here is a comparability desk that outlines the variations between Management Level (CP), Important Management Level (CCP), Prerequisite Program (PRP), and Operational Prerequisite Program (oPRP):

| Side | Management Level (CP) | Important Management Level (CCP) | Prerequisite Program (PRP) | Operational Prerequisite Program (oPRP) |

|---|---|---|---|---|

| Definition | Any step the place organic, chemical, and bodily hazards might be managed. | A step at which management might be utilized and is important to forestall or remove a meals security hazard or scale back it to a suitable stage. | Fundamental situations and actions needed to keep up a hygienic setting all through the meals chain. | Measures and actions used to regulate the chance of excessive ranges of recognized dangers within the manufacturing course of. |

| Function in Security | Might or might not be crucial in eliminating hazards however contribute to their prevention and discount. | Important in eliminating meals security hazards or decreasing them to a suitable stage. | Management low and reasonable threat ranges and keep sanitary situations to forestall meals issues of safety. | Particular to regulate recognized high-risk hazards, based mostly on in-depth hazard evaluation. |

| Instance | Prewashing potatoes to remove bodily hazards earlier than blanching. | Cooking meals to protected inside temperatures to kill dangerous micro organism. | Correct worker hygiene, handwashing, pest management, and primary sanitary design. | Particular measures like a selected cleansing course of for a chunk of apparatus recognized as a threat level. |

| System | HARPC (Hazard Evaluation and Threat-Based mostly Preventive Controls) | HACCP (Hazard Evaluation and Important Management Factors) | HACCP (As the inspiration) | Varies based mostly on meals regulatory requirements (nation or business particular) |

| Focus | Common management of hazards, not essentially crucial factors. | Particular crucial steps the place hazards should be managed to forestall security dangers. | Common upkeep of hygiene and operational requirements all through the meals chain. | Targeted on controlling particular hazards recognized as excessive threat within the course of. |

| Software | Used all through the method wherever management might be utilized. | Utilized solely at crucial steps the place failure to regulate a hazard may lead to unacceptable well being dangers. | Common utility to assist HACCP, not centered on particular steps however important for general security. | Utilized at particular factors or for particular tools/processes the place recognized excessive dangers should be managed. |

Management Level (CP)

A Management Level is any step the place any organic, chemical and bodily hazards might be managed. This time period is usually used for processes that will or might not be crucial in eliminating hazards however contribute to their prevention and discount. An instance of a management level could also be prewashing potatoes to remove any bodily hazard earlier than blanching, which serves a unique objective. Management Level is a live performance used within the HARPC meals security system.

Important Management Level (CCP)

One of many key HACCP ideas, a CCP refers back to the step at which management might be utilized and is important to forestall or remove a meals security hazard or scale back it to a suitable stage. If the potential hazard might be decreased or eradicated in one other upcoming course of, a management level will not be crucial. The clearest distinction between a CP and a CCP is that CCPs are the ultimate step at which you’ll be able to scale back hazardous contaminations to a suitable stage. The time period CCP relies on the ideas of HACCP.

Prerequisite program (PRP)

Obligatory primary situations and actions which can be wanted to keep up a hygienic setting all through the meals chain. You’ll be able to management low and reasonable threat ranges by placing sturdy PRPs in place. Prerequisite applications are easy rules similar to correct worker hygiene, handwashing instructions, pest management, and primary sanitary design ideas.

These applications promote sanitary situations to forestall meals issues of safety and keep clear services. Because the identify suggests, prerequisite applications are wanted to determine a HACCP meals security plan with a stable basis and are thought of their primary framework. Examples of prerequisite applications for HACCP may embody high quality assurance procedures, labeling, customary working procedures, and recipes.

Frequent prerequisite applications could embody:

- Sanitation Customary Working Procedures (SSOP)

- present Goon Manufacturing Practices (cGMP)

- Building and structure of buildings,

- The structure of premises,

- Air, water, and vitality provides

- Receiving items and storage

- Manufacturing tools

- Measures for the prevention of cross-contamination

- Pest management

- Traceability and recall

- Employees hygiene

- Cleansing and sanitizing

Operational prerequisite program (oPRP)

Intermediate measures and actions used to regulate the chance of excessive ranges of recognized dangers within the manufacturing course of. Using OPRPs is dependent upon meals regulatory requirements and varies from nation to nation. Operational prerequisite applications aren’t normal steps, however quite particular to regulate sure hazards. These applications are the results of in-depth hazard evaluation.

To place a distinction between PRP and oPRP, prerequisite applications are normally normal to the method and never centered on any specific step within the course of stream. For instance, cleansing and sanitizing are actions that may apply to all steps, rooms, and objects.

If you wish to determine which management measures are applicable to determine hazards in your meals enterprise, it is best to consider the chance ranges utilizing a crucial management level determination tree diagram or a threat matrix or use digital options to meals security. Alternatively, you need to use our free CCP software to find out the kind of operation wanted to regulate a selected hazard. All it’s important to do is determine the hazard of concern, the chance of its incidence, and the potential impact that it might have in your operations. Our free software will then present the right operation that you will want.

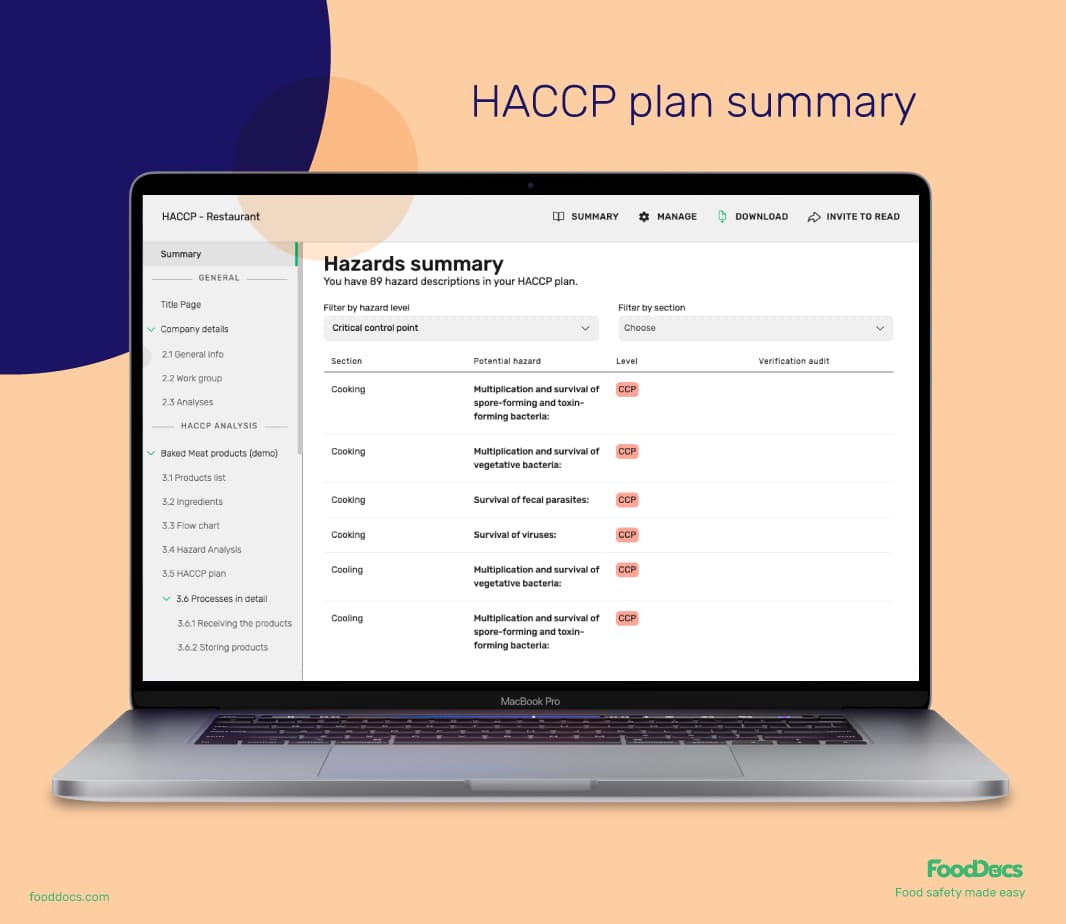

Desire a quicker answer? Our built-in HACCP plan builder can assist you fulfill all parts of a HACCP plan in simply a mean of 1 hour. Our built-in software program mechanically generates the entire most vital paperwork of your HACCP plan, together with the identification of CCPs. What’s extra is that you may customise the recognized CCPs, add extra operations, or modify them as an OPRP. Our system presents the quickest and most handy manner towards meals security and HACCP compliance.

Learn extra about OPRP and the variations between CCP and PRP right here.

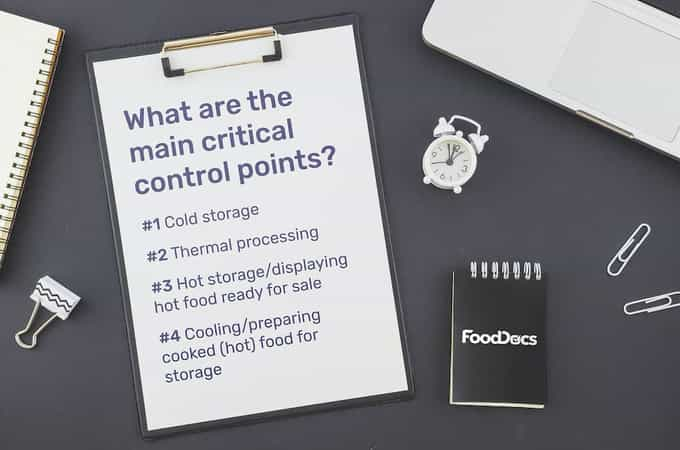

What are the commonest critical control factors?

As you already know by now, there are no generic CCP templates that match all meals companies. Solely you possibly can resolve what potential meals high quality hazard is relevant to your restaurant, burger truck, or café. Important management factors fluctuate relying on the character of the meals institution you will have.

Totally different eating places that put together related meals can nonetheless determine totally different hazards and have totally different CCPs and preventive measures. This could depend upon the structure of the meals processing facility, tools, substances used, kind of meals produced, processes employed, and so forth. In case you are uncertain whether or not a sure step ought to depend as a CCP, put it on the record for analysis.

Correct identification of CCPs is a job of your HACCP meals security staff consisting of specialists within the numerous fields of your course of. A crucial management level is at all times associated to hazards and might fluctuate in nature relying on the recognized meals security threat. Meals hazards might be organic which incorporates micro organism, fungi, viruses, and different pathogenic microorganisms; chemical, similar to chemical toxins, preservatives, and pesticides; or bodily which might be within the type of items of hair, glass, or steel shards.

Important management factors for organic hazards are normally depending on the physicochemical properties of your meals product. The expansion of micro organism and different pathogens is affected by dietary properties, acidity stage, moisture stage, water exercise, salt focus, smoke level, and others. When it comes to chemical contaminations, CCPs might be based mostly on the diploma of processing, uncooked supplies used, and added preservatives.

Lastly, CCPs for bodily contaminants are principally based mostly on the origin of the uncooked supplies and sanitation of the processing space and that of the provider.

Listed below are some widespread crucial management factors and their primary ideas that will apply to most institutions within the meals business:

1. Chilly storage

Chilly storage is usually a CCP for various causes. For instance, for those who provide uncooked meat to your clients, chilly storage instantly turns into a CCP.

The precept behind utilizing chilly storage for storing and transporting contemporary or uncooked merchandise is that at low meals temperatures, all organic processes are slowed down and even stopped. Such organic processes embody enzymatic (e.g. browning in vegatables and fruits, and proteolysis in fishes and meats) and microbiological reactions.

Chilly storage prevents the breakdown of the standard of your meals as a result of it stops microorganisms from multiplying, typically even eliminating them, and prevents pure enzymatic breakdown happens. Likewise, refrigerating precooked meals to forestall hazardous microorganisms from multiplying is one more reason for utilizing chilly storage.

Fluctuations in temperature management preserving could assist enteric pathogens to thrive by giving them time to get well and bringing the microbiological high quality to unsafe ranges and producing hazardous meals. As well as, drastic adjustments in surrounding temperature could typically trigger softening of meals tissues particularly when they’re frozen. Throughout transport, in case your meals merchandise are supposed to be delivered inside chilly storage, which means that they have an inclination to spoil if ambient temperatures are used.

2. Thermal processing

Any particular warmth course of that’s designed to destroy a particular microbiological pathogen at a particular time and temperature can usually grow to be a CCP. Thermal processing procedures are normally used for cooking protected meals merchandise similar to canning, baking, and pasteurizing milk. Regardless of this, the precept of their use in a course of can decide if they are often thought of a crucial management level.

Take canning and pasteurization as examples. In these processing strategies, thermal processing is used to not prepare dinner the product, however to render them protected from microbial contamination. The components affecting canning such because the time-temperature mixture used for the method are decided by the goal microorganism in low-acid meals which is Clostridium botulinum.

Alternatively, though the same idea is at play, pasteurization time-temperature mixtures are meant for killing the microbial pathogens Coxiella burnetti and Mycobacterium tuberculosis. All of those pathogens are recognized to trigger extreme human well being hazards similar to hospitalization and demise. In some instances, their presence and different enteric pathogens have been the trigger for a enterprise to grow to be closed. Because of this microbiological testing for his or her presence is a regular in these meals operations.

Skipping these processes or not adhering to the right requirements could trigger meals issues of safety for your corporation, and due to this fact they’re thought of crucial management factors. Within the case of baking, thermal processing is just wanted to remodel dough into bread. If the established parameters aren’t met, no important meals security subject could come up. At most, the one drawback could also be underbaking or overbaking your meals merchandise.

When it comes to chemical hazards, thermal processing limits may also be utilized. For merchandise which have the suitable mixture of proteins and carbohydrates, overprocessing can result in the formation of acrylamide. This substance is a recognized carcinogenic agent and is fashioned when your product is excessively heated. As such, avoiding unacceptable ranges should be adopted.

3. Sizzling storage / displaying sizzling meals prepared on the market

When your completed product is pre-cooked and bought as sizzling meals, it must be saved at 140°F (60°C)or above to forestall micro organism from multiplying whereas the meals is on show or saved. The required temperature must be uniform round and throughout the meals. It is a quite common CCP for accommodations, college cafeterias, and sizzling canine stands, amongst others.

The precept behind that is preserving your meals away from the temperature hazard zone which is 40°F to 140°F (4°C to 60°C) or the vary of temperature the place most enteric pathogens thrive. As a rule of thumb prepared, it’s not suitable for eating merchandise from meals providers that aren’t presupposed to be outdoors this zone for greater than 2 hours.

4. Cooling/getting ready cooked meals for storage

Meals that has been cooked might be unnoticed at room temperature till it cools down sufficient to be put into the fridge. The cooling should occur as quick as doable and totally different international locations have totally different requirements in relation to the temperatures the meals should attain throughout the first 2-4 hours.

The explanation behind this CCP is that the longer your meals takes to chilly down, the extra probability of surviving microorganisms to multiply will increase. An abrupt temperature change will additional harm microorganisms and reduce their survival charge. The identical precept applies to the thawing of meals. As you thaw your frozen meals, microorganisms which have survived can have the time to get well.

Learn extra about totally different crucial management level examples.

What are different CCPs within the meals business?

Toxin testing

This technique might be thought of as a crucial management level for merchandise which can be thought of high-risk. An instance of high-risk merchandise can be peanuts, corns, and different grains. In case you are within the business of peanuts and cereals, you’re most actually conversant in how vital the degrees of Aflatoxin are. This compound is a toxin produced by microorganisms below the genus Aspergillus. Aflatoxin is a extremely regulated organic toxin due to its antagonistic results on people and animals and is most normally discovered within the talked about merchandise. As such, its detection throughout receiving is essential.

Meals remembers in previous associated to this compound are recorded. Failure to detect breaches of acceptable ranges could trigger lack of management of security, shopper complaints, human well being hazards, and lawsuits. Uncooked supplies are inspected and held within the storage warehouse earlier than acceptance. As soon as confirmed away from contaminants, they’re accepted to be used.

Filth detection course of

This step is usually thought of as a normal crucial management level to watch, detect, and management bodily hazards. Filth detection in a meals processing facility might be carried out in many various methods. Apart from visible observations, one other instance can be sieving a pattern batch of flour out of your storage space. Utilizing a particular dimension of sieve that can solely permit the flour to move by way of will immediate your high quality assurance specialists and meals security supervisor if there are bodily contaminants.

These contaminants are normally damaged glass, items of metals, items of bijou, and different sharp objects. Different strategies might be carried out utilizing a magnet or a steel detector to gather steel contaminants. These bodily hazards could cause damage if ingested by shoppers. The dimensions of those filths is normally used as a bodily parameter to find out the chance they’ve. As soon as they go undetected in inspection, they will simply work their strategy to the completed product.

Product formulation management

Throughout manufacturing, the required quantity of substances and uncooked supplies are supplied to your in-line workers. Preweighed substances are normally delivered to the manufacturing and are prepared to be used. The product formulation management level is finished by verifying the quantity of those supplies earlier than use.

Exceeding or missing the allowable or required weights and quantities, respectively, of sure merchandise similar to preservatives or different substances can result in well being hazards. If too little acidulant is added to your meals product which is predicted to have a low pH stage, microbiological hazards could multiply on this situation and create a meals high quality hazard.

Allergen cross-contact prevention

Whereas allergen controls (e.g., devoted tools or cleansing protocols) are sometimes thought of PRPs, if a particular step is the final level to forestall a extreme allergen hazard, it may be handled as a CCP.

Conducting a hazard evaluation and figuring out crucial management factors is usually a time-consuming process. To not point out that in case you are fairly inexperienced and your HACCP meals security staff lacks specialization, there are probabilities that you simply would possibly miss some crucial management factors. This truth could then lead you to rent a meals security marketing consultant and might value you quite a bit.

Fortunately, these days are over. FoodDocs, your digital answer for meals security administration system can decide the CCPs in your operations and processes easily and rapidly. Our built-in software program can mechanically determine the CCPs in your meals operation based mostly on the character of your corporation with only a few clicks.

You’ll be able to even generate monitoring kinds for various duties similar to thermal monitoring procedures, pest management, and different paperwork which can be utilized as a complete verification process and management CCPs. We goal to make your lives simple and for meals security to be accessible to everybody.

The best way to determine CCPs

One of the crucial efficient methods to determine Important Management Factors is to make use of a call tree, which consists of a set of questions designed to reach at conclusions of whether or not or not a management measure is crucial.

As outlined in our HACCP determination tree information:

The usual determination tree developed by the Codex Alimentarius Fee, a bunch developed to determine worldwide pointers for meals management programs for the safety of public well being, is used as the premise for many determination timber. To guard your supposed shoppers, you will need to conduct all phases of hazard evaluation and carry out ample actions such because the implementation of CCPs to regulate them.

Why do we have to determine CCPs?

When dealing with meals, you want to research and describe which management measures might be utilized for every hazard. Many preventive management measures are put in place to keep away from meals contamination from the manufacturing setting (e.g., workers, pests, water provide, and so forth.), however different measures goal to scale back or remove hazards straight linked to particular manufacturing processes. (These can result in the institution of CCPs or operational PRPs – extra about these later.)

A crucial management level is established after the hazard identification and evaluation in your manufacturing course of. Evaluation of hazards is normally carried out through the use of established scientific research, opinions from specialists, and meals legal guidelines and rules. Loads of time goes into the identification and validation of which operations might be thought of as CCPs.

After figuring out which hazards are current, a crucial management level might be evaluated for project. A way is taken into account a CCP if there is no such thing as a different subsequent step that can reduce or remove the potential hazard current within the product. Which means that the method should be efficiently executed. A sequence of things are thought of earlier than a course of step is taken into account as a crucial management level. Because of this it’s useful to make use of a threat matrix or a call tree diagram to determine the chance stage of every step of the entire course of and supply an in depth clarification and justification.

When conducting a hazard analysis, contemplate the chance of publicity and the severity of the potential penalties if the hazard will not be correctly managed. Severity is the seriousness of the results of publicity to the hazard (for instance, the magnitude and length of sickness or damage and the results). You’ll be able to use the next to guage the doubtless incidence of a hazard:

- Your expertise

- Epidemiological knowledge

- Data within the technical literature

Should you select to make use of a call tree to find out the dangers of every step within the strategy of meals dealing with, do not forget that multiple step in a course of might be concerned to regulate a hazard, and multiple hazard could also be managed by a particular management measure.

As a rule, you want to find out which steps apply to your corporation and the place the potential hazard may come from. Upon getting recognized all of the hazards and their threat ranges, you need to be sure that you place controls and applicable corrective actions in place for every one in all them.

All of those duties can simply be carried out utilizing our meals security software program. You’ll be able to maintain information in our software program system, arrange your procedures for monitoring, and control the information within the exercise log. Utilizing the options of our digital meals security system, you possibly can depart the evaluation to us and allow us to recommend that are crucial crucial management factors of your meals processing plant.

Together with this suggestion, you possibly can even generate your monitoring kinds for every CCP, obtain them, and print them for the entire HACCP staff. The most effective half is you shouldn’t have to attend lengthy. The entire strategy of shifting to a digital meals security administration system will solely take quarter-hour.

Routinely determine Important Management Factors and get a HACCP meals security system in lower than 1 hour

Conducting a hazard evaluation, figuring out crucial management factors, and each different process concerned in making a HACCP plan is time-consuming and infrequently costly.

What if there’s a manner so that you can do all these duties with a way that’s 500x quicker and 15x cheaper? Our built-in meals security software program at FoodDocs was developed that can assist you get by way of all of the HACCP paperwork with out breaking a sweat. Our HACCP program builder was designed to generate probably the most related hazards, crucial management factors, management measures, and validation actions match for your corporation.

A few of the issues we are able to do for you embody:

- create a stream diagram of your meals enterprise,

- hazard identification and evaluation,

- set up crucial management factors,

- create monitoring information as preventive measures to your CCPs,

- generate common monitoring procedures of your course of,

- automate repeated duties

- ship you alerts and notifications for due dates and monitoring duties,

- set up duties and conduct correct report preserving for you, and

- replace you with latest adjustments on the legal guidelines and rules round your space

By no means fear once more about learn how to determine CCPs to your HACCP meals security program with FoodDocs. Our system mechanically ranks the hazards in your meals operations based mostly on our established threat evaluation matrix. We mechanically recommend the suitable stage of exercise for every hazard.

Motion ranges fluctuate as PRP, oPRP, CP, or CCP. Our recommendations are based mostly on the information of our meals security specialists, associated literature, and data from our clients in related meals companies as yours. By way of this mixed data, you might be assured that every one paperwork and knowledge we offer are correct.

As well as, we perceive that some international locations and meals firms have particular crucial management operations which can be very distinctive. Because of this we permit our clients to enter new hazards and management measures of their HACCP plan. All it’s important to do is determine the hazard, enter its stage of chance and severity of potential harm, and we’ll mechanically recommend which motion stage is most applicable for this hazard.

Our providers even include a free 14-day trial sufficient so that you can construct your complete HACCP plan. Full your HACCP plan inside simply 1 hour and obtain and print it for your entire workers. You’ll be able to even invite meals security auditors to view your digital HACCP plan to save lots of on printing it! Construct your HACCP plan sustainably and effectively.

Ceaselessly requested questions on Important Management Factors