Try our newest merchandise

Some of the well-known systematic approaches to meals security is the Hazard Evaluation Vital Management Level (HACCP). This program helps management and stop the danger of meals hazards from inflicting any foodborne sickness.

Breaches of requirements could generally outcome from human error, gear malfunction, and others. That is the place the fifth precept of HACCP plan-making comes into play: establishing corrective actions. In making a corrective motion plan, applicable duties are ready to deal with operations that will have potential deviations.

When meals security methods break down, the results cascade past well being impacts. Companies face devastating monetary losses, broken reputations, and potential authorized motion. But many meals firms nonetheless deal with corrective motion plans as mere paperwork. However it is a important mistake.

Key factors lined:

- Corrective motion is a process utilized to appropriate deviations from important limits in a HACCP plan.

- A corrective motion plan consists of detailed directions on find out how to establish and tackle the basis causes of deviations.

- Corrective actions are important for stopping foodborne sicknesses by addressing breaches in meals security requirements.

- These actions are primarily based on established important management factors and their corresponding important limits.

- The plan is proactive, aiming to resolve deviations earlier than they compromise meals security.

- Corrective actions could contain easy changes like recalibrating gear or extra complicated options like redesigning a course of.

- Efficient corrective actions are measurable and verifiable, guaranteeing they tackle the deviation adequately.

- In a HACCP plan, corrective actions ought to be recognized for each important management level to make sure complete threat administration.

- Coaching and consciousness are essential for guaranteeing employees can implement corrective actions successfully.

- FoodDocs’ meals security administration software program can help in establishing corrective motion plans by producing custom-made actions primarily based on the precise wants of a meals enterprise.

What’s corrective motion in meals security?

Corrective motion is a direct and meant step taken to deal with non-compliance of allowable important limits at any operation. This operation is carried out inside an inexpensive time-frame in an try to return the breached parameters to acceptable limits.

In the meals business, non-compliance and deviations in important limits could imply that the danger of inflicting foodborne sicknesses will considerably enhance. Corrective motion is usually a easy step, akin to recalibrating a bit of kit to extremely technical operations that contain recomputing for various working parameters.

In a meals institution, together with different industries, corrective motion have to be established in anticipation of any potential non-compliance. This step doesn’t imply that workers can loosen up with their meals dealing with practices as a result of applicable corrective actions are in place.

The appliance of corrective motion could cause a rise in materials and labor prices. Generally, corrective motion can land on a choice to eliminate non-compliant merchandise to guard the shoppers from damages.

What’s a corrective motion plan?

A corrective motion plan is an overview of steps wanted to resolve errors or non-compliance and to maintain them from taking place once more. When it comes to the HACCP rules, a corrective motion plan is created in preparation for any deviations from established important limits. This plan is created to forestall hazardous meals from reaching potential prospects and inflicting foodborne sicknesses or buyer complaints.

A corrective motion plan is a vital a part of your HACCP plan. It’s your meals enterprise workforce’s protection in case of unusual deviations. As such, your workforce should have the ability to fulfill all steps to make sure an efficient corrective motion plan.

In another business, a corrective motion plan employs having SMART objectives. This acronym describes the fascinating qualities of an efficient corrective motion plan.

- Particular

- Measurable

- Attainable

- Related

- Time-based

In a HACCP plan, corrective actions are depending on the recognized important management factors and their corresponding important limits. Conducting corrective motion should at all times be monitored for corrective motion studies.

This step produces evaluation data that may function proof that the merchandise are both protected, or a simply trigger was recognized to eliminate them. As well as, specific metrics are established to establish whether or not a corrective motion plan is profitable in containing deviations.

To watch the applying of this operation, a HACCP corrective motion plan template such because the one proven beneath from the Meals and Drug Administration should at all times be ready.

What are the advantages of a corrective motion plan?

The primary advantages of an efficient corrective motion plan which might considerably improve operations inside a meals manufacturing or dealing with surroundings are:

- Ensured compliance: It ensures adherence to meals security laws and requirements akin to HACCP, FDA, or ISO 22000. This compliance is important for avoiding authorized points and sustaining the belief of shoppers and stakeholders.

- Enhanced product high quality: By addressing the basis causes of high quality deviations, corrective motion plans assist preserve excessive requirements in product high quality. This immediately impacts client satisfaction and reduces the danger of expensive remembers.

- Operational effectivity: These plans assist streamline processes by figuring out and eliminating sources of inefficiency. This may end up in quicker manufacturing occasions, decreased meals waste, and decrease prices.

- Danger discount: Proactively coping with potential meals security hazards earlier than they result in incidents helps reduce well being dangers to shoppers and monetary dangers to the corporate.

- Worker engagement: Involving workers within the improvement and implementation of corrective actions not solely enhances the effectiveness of those measures but in addition boosts morale and dedication to meals security tradition.

- Buyer belief and retention: Swift and efficient correction of points reassures prospects in regards to the reliability of your security practices, fostering belief and inspiring repeat enterprise.

- Steady enchancment: Corrective motion plans are integral to a steady enchancment technique, guaranteeing that your operations evolve to satisfy present and future challenges in meals security and high quality.

At what level in a HACCP plan ought to corrective actions be recognized?

HACCP corrective actions are established for each important management level and its important limits. A HACCP corrective motion plan is made specifically for particular operations. They’re designed to manage potential deviations on a meals security process and, subsequently, have to be associated to a important management level operation.

Below this precept, the next are recognized for a corrective motion plan:

- Corrective motion step

- Assigned worker to carry out corrective motion

- Applicable corrective motion documentation

Members of your HACCP workforce who’re well-versed with the HACCP plan, the method, and the character of the product are probably the most perfect candidates to carry out a corrective motion process. As soon as corrective actions are utilized, the experience of the meals security supervisor have to be sought to gather a corrective motion resolution for the merchandise affected by the deviation.

What is the distinction between corrective motion and preventive motion (CAPA)?

Aside from the corrective actions utilized within the fifth precept of the HACCP system, a distinct system known as the Corrective and Preventive motion or CAPA system exists. The CAPA course of is used to deal with points at any a part of your meals enterprise administration controls together with:

- Manufacturing and course of controls

- Service studies

- Gear and facility

- Supplies

- Design

- Information, paperwork, and alter controls

The primary goal of a CAPA course of is to gather and analyze data and to foretell and foresee meals security and high quality administration to ascertain actions that may forestall or management them from occurring. Do not forget that correction and preventive motion procedures are two completely different operations. They’re utilized in numerous sections of the working system however are equally essential. Applicable monitoring methods and verification procedures should at all times be applied along with these actions.

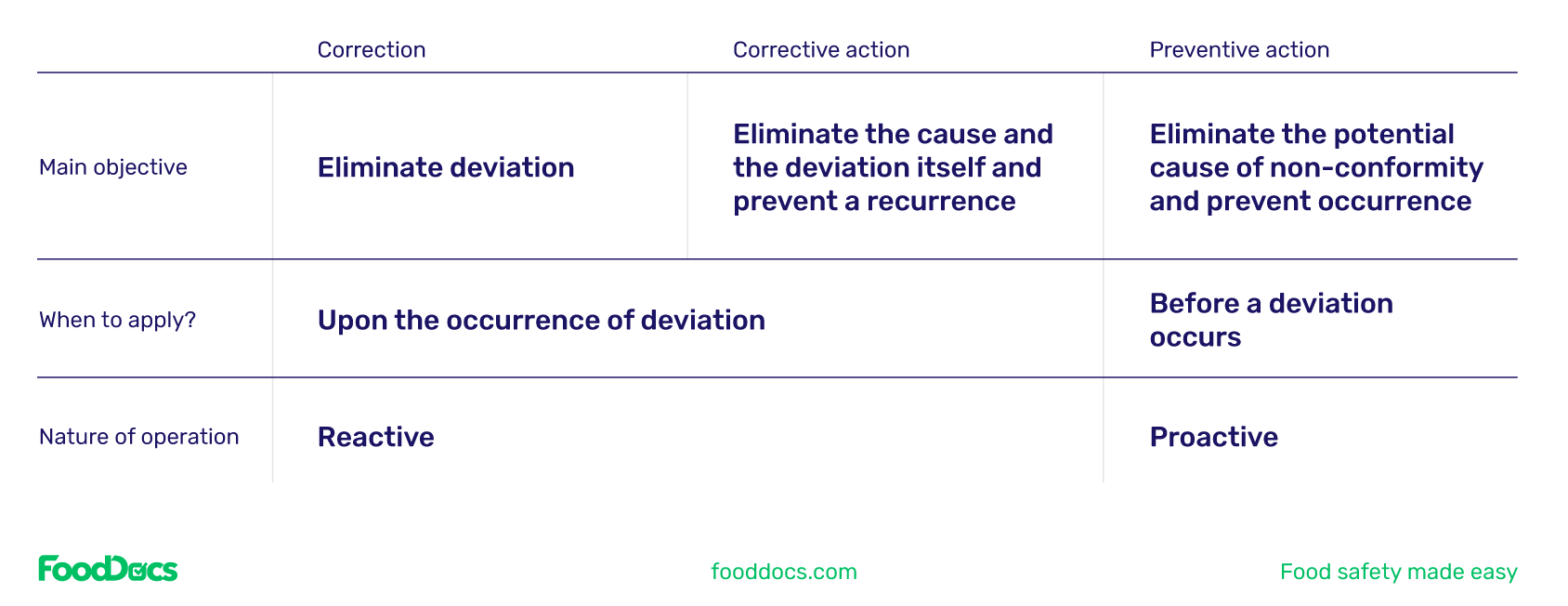

A CAPA course of consists of three completely different operations:

- Correction

- Corrective motion

- Preventive motion procedures

Though these could appear all related, these operations are very distinct. Here’s a abstract of their variations:

Based mostly on the High quality Administration System Regulation FDA 21 CFR 820 in america, it’s a regulatory requirement for producers to ascertain procedures for corrective and preventive actions. The CAPA is a system beneath the prerequisite program Good Manufacturing Practices and contributes to the effectiveness of a HACCP plan.

write a corrective motion plan

A corrective motion plan is used to resolve systemic issues and any core problem. As such, it tries to focus on the basis reason behind potential issues. An essential essence of corrective motion steps is the foresight of potential business points. Enough and dependable particulars are main keys to creating an efficient corrective motion plan.

If it’s your first time making a corrective motion program, it might be greatest to take issues slowly and use this step-by-step instruction. Every step is essential to make the plan efficient.

A corrective motion information consists of those main steps:

1. Determine all deviations from important limits

To grasp the suitable motion, enough data on the issue have to be collected. Questions akin to “What’s the downside at hand?” and ” How did the issue happen?” have to be appropriately answered for correct evaluation. At this level, the assigned worker can decide if the issue is an issue with high quality requirements or a security problem.

Use gathering strategies like worker interviews, common inspections, and audits of present data. File each discovering clearly, as thorough documentation is essential all through this course of.

Use instruments like checklists and digital reporting methods to make sure no potential hazard slips via the cracks. Documentation ought to seize each element about what went improper, together with when it occurred, who was concerned, and any rapid impacts. The important thing to success on this step lies in capturing the complete scope of the issue for higher evaluation and resolution formulation.

2. Take applicable corrective actions to resolve non-compliance

Whether or not a product high quality or a security problem, the issue have to be instantly handled. Particularly within the meals manufacturing firm the place merchandise are generally produced by the second, rapid corrective motion have to be utilized to forestall the issue from inflicting an even bigger impact. Corrective actions should at all times be justifiable, measurable and will be utilized in real-time to make sure their applicability at any level in meals processing.

3. Decide the reason for deviation

In distinction with correction, a corrective motion includes figuring out the basis reason behind the deviation. By this, the recurrence of the issue will be prevented. At this level, a complete root trigger evaluation and information gathering from an goal investigation have to be performed.

As Abbie Llanes wrote for Secure Meals Alliance:

As soon as a root trigger is recognized, be sure you discover a resolution that totally addresses the difficulty. For those who don’t, it is rather potential the issue will occur once more. CAPA investigators continuously establish non-conformity as a root trigger, thus resulting in develop an ineffective resolution.

Root trigger evaluation will be enhanced by asking iterative “why” questions (i.e., the 5 Whys) or a Fishbone Diagram. This method helps dig deeper into the underlying points past the signs.

For instance, if contamination occurred, ask why it occurred, then ask why once more primarily based on the primary reply, till reaching the basis trigger. Questions akin to “What led to the issue from occurring?” could also be requested to evaluate the scenario. Do not forget that the shortage of correct data can result in an inefficient corrective motion plan the place the issues should still recur.

4. Implement the corrective motion plan

Determine on a disposition for the non-compliant meals merchandise. For manufacturing firms, non-compliant or faulty merchandise, though utilized with corrective actions, will be inadequate for the corporate compliance requirements. As such, inclinations akin to whether or not to transform, reconstitute, or dispose of those have to be made. In deciding what to do with non-compliant meals merchandise, the security of shoppers should at all times come first.

Implementing the plan requires proactive communication between departments. Inform all related employees of their roles. Use briefings, written directions, and steady coaching periods to make sure everybody understands what’s anticipated. Think about having common check-ins to strengthen obligations and get suggestions on progress.

5. Validation strategies for the effectiveness of the corrective motion and document

To make sure that the corrective actions have been correctly utilized and that their goal has been achieved, validation strategies have to be in place. These data function proof and reference if complaints on the affected merchandise come up. Moreover, they will also be important instruments for traceability functions.

Different data such because the accountable worker and the time wanted to carry out the corrective motion should even be added. A corrective motion plan is a flexible system. It may be utilized for the prevention of high quality issues and meals questions of safety. At occasions, additionally it is used to resolve administration points and worker applications.

Just like different methods, sufficient coaching supplies and fixed monitoring are essential to realize the utmost outcomes of a corrective motion plan. Extra coaching applications assist educate workers find out how to create a corrective motion plan and implement it in on a regular basis and present operations.

In some instances within the business, new operations would want their evaluation and new hazards and significant management factors will be recognized. In such a case, a corrective motion request will be filed for the creation of a brand new corrective motion plan for this operation.

What are examples of a corrective motion plan?

To raised perceive find out how to create this plan, listed here are some corrective motion examples primarily based on among the most typical important management factors within the meals business.

Corrective motion plan instance #1

Perishable meals akin to recent meat and greens should at all times be stored in refrigerated circumstances. Explicit for meat, this uncooked materials have to be saved at 28°F to 32°F (-2°C to 0°C) to manage the expansion of microbial pathogens. How ought to a meals worker tackle the scenario if the fridge thermometer reads 59°F (15°C)?

|

What’s the downside? |

|

Important deviation from the important restrict 28°F to 32°F (-2°C to 0°C). |

|

What ought to be completed? (Corrective motion) |

|

Test if the fridge is malfunctioning. If sure, consider all healthful meals and switch them to a functioning fridge and ship the malfunctioning fridge to upkeep. Discard meals which have been spoiled due to the deviation. |

|

Why ought to this motion be completed? (Justify corrective motion) |

|

Meals spoilage is time-sensitive. If the uncooked supplies are left at an unsafe temperature, the danger of inflicting foodborne sickness will increase. To forestall this from taking place once more, the fridge have to be despatched to upkeep for correct repairs. |

|

Who will do it? |

|

Meals handler assigned with monitoring storage temperatures. |

|

The place will or not it’s completed? |

|

Storage space. |

|

When will or not it’s completed? |

|

Instantly upon detection. |

On this corrective motion plan instance, the rapid corrective motion is to make sure that the uncooked meats are saved at correct storage temperatures to forestall spoilage. To forestall this from taking place once more, the fridge will be despatched for recalibration or complete upkeep to find out the basis downside.

On this instance, you will need to establish the important limits which have been breached to make sure that there’s a deviation. This deviation will help level out just a few causes for the reason for the deviation.

Corrective motion plan instance #2

In meals processing, reaching the really useful inside temperature is without doubt one of the most essential standards to make sure meals security. For meals akin to hen or poultry meat, the really useful inside temperature may be very strict. Poultry meat should at all times be cooked to an inside temperature of 165°F (74°C). What can be the corrective motion if the oven can’t course of hen dishes to this inside temperature?

|

What’s the downside? |

|

The oven can’t course of hen dishes to 165°F (74°C) inside temperature. |

|

What ought to be completed? (Corrective motion) |

|

Cease processing. Separate affected batches. Alter cooking parameters to realize the goal inside temperature. Ship oven for recalibration and upkeep. |

|

Why ought to this motion be completed? (Justify corrective motion) |

|

To proceed restaurant service, enhance the oven temperature to achieve the goal inside temperature. The issue could also be due to an uncalibrated thermometer. Use a handbook thermometer to confirm cooking temperatures. |

|

Who will do it? |

|

Meals handler assigned with cooking the poultry dishes. |

|

The place will or not it’s completed? |

|

Kitchen space. |

|

When will or not it’s completed? |

|

Instantly upon detection. |

Corrective actions don’t at all times should be a single operation. Generally, to deal with an issue, a set of extra actions have to be utilized. On this corrective motion plan instance, the manufacturing of hen dishes can’t be stopped since service remains to be ongoing. If the issue is with the thermometer studying, relevant actions can contain meals handlers switching to a handbook meals thermometer for correct outcomes. Quickly after service, the oven will be despatched for recalibration and upkeep work. That is a part of the corrective motion administration.

Affected supplies can both be reworked or disposed of relying on the disposition of the meals security supervisor.

In different conditions, corrective motion duties will be any of the next:

- Disposing of spoiled meals.

- Growing the holding temperature above the temperature hazard zone.

- Rejecting provides with observable main defects.

What’s an instance of a weak corrective motion?

Corrective motion methods that rely upon variable elements akin to reminiscence, recall, and memorization of written insurance policies are thought-about weak. The actions should not rely upon the staff however quite on the method itself, which is much less variable than a human behaviour problem.

Some examples of operations that make a corrective motion plan weak could embody:

- Double-checking the method

- Warning indicators

- New laws

- Repeated worker coaching

How can FoodDocs provide help to create a corrective motion plan?

Within the meals business, the HACCP program was established to considerably cut back the extent of threat of foodborne sicknesses due to meals security hazards. Whereas this program is a scientific method, it doesn’t assure the entire elimination of those dangers.

At FoodDocs, we will help you are taking out the tedious strategy of figuring out these corrective actions for all your important management factors. Our built-in software program HACCP plan builder will help you full all 7 rules of HACCP in simply a mean of 1 hour by robotically producing a complete HACCP plan primarily based on what you are promoting operations.

This implies you may robotically get complete and intuitively prompt corrective actions for any potential breach in your operations.

How? By utilizing synthetic intelligence and your solutions to our fundamental questions, our system analyzes and generates an entire HACCP plan primarily based on the character of your meals enterprise. It might probably give you the entire most essential HACCP paperwork that may provide help to attain HACCP meals security compliance.

Listed here are a few of what our HACCP plan software program affords:

- Precisely recognized and analyzed meals security hazards in your operations.

- Full important management factors and corresponding important limits.

- Corrective actions for any deviation on every important management level. These corrective actions are intuitively set to robotically pop up from our cell software as decisions each time a breach of requirements happens. This function can simply information meals workers with which corrective motion to carry out.

- Routinely set monitoring procedures and kinds for all important operations.

What makes our system an excellent higher match even fitter in your meals enterprise is that we enable your meals security supervisor to customise the prompt corrective actions and different essential paperwork. This function will enable your workforce so as to add operations which can be distinctive to your meals enterprise.

With our built-in digital HACCP plan builder, it can save you as much as 500x extra time out of your HACCP starting stage with no revisions. As well as, our system is powered by synthetic intelligence and the steering of meals security specialists who’ve labored within the meals business for a number of years. Relaxation assured, our robotically generated HACCP plans for you’ll be able to provide help to get compliant very quickly.

Switching to a digital platform has by no means been this straightforward. Moreover, you’ll be able to simply share your digital HACCP plan with meals security enforcement authorities for audit or inspection functions. If they like the normal method, you’ll be able to at all times obtain your HACCP plan, print it, and submit it to your native meals security company.

With our digital HACCP plan builder, you’ll by no means have to fret about whether or not your corrective motion plan is suitable in your operations or not. Get the steering of meals security specialists by becoming a member of us at FoodDocs. Begin your HACCP plan-making journey with our free, 14-day trial.

Incessantly requested questions on corrective actions