Try our newest merchandise

Each meals enterprise within the meals business has its distinctive operations and meals security hazard based mostly on the services and products that they use. As such, all meals companies are anticipated to have meals security administration programs which can be well-structured based mostly on these operations.

These programs would come with constructing a Hazard Evaluation Essential Management Level (HACCP) plan the place any meals security dangers and any potential hazards associated to your processing facility and operations are listed, analyzed, and addressed by the meals security staff.

And that includes figuring out what important management factors don’t embody and what they do.

Key takeaways

-

Essential management factors are important in stopping or eliminating meals security dangers to acceptable ranges inside a meals enterprise.

-

Each meals enterprise ought to have a structured meals security administration system, tailor-made to their particular operations and hazards.

-

Constructing a Hazard Evaluation Essential Management Level (HACCP) plan is essential, involving identification, evaluation, and administration of meals security dangers.

-

Operations associated to the standard of meals, equivalent to garnishing, don’t represent important management factors in a HACCP plan.

-

Essential management factors deal with meals security moderately than high quality, affecting operations like cooking or cooling which immediately affect product security.

-

Prerequisite applications, whereas essential for sustaining meals security, don’t management particular hazards like CCPs do however help total meals security administration.

-

Figuring out important management factors requires cautious consideration and a scientific method to make sure right implementation.

-

High quality management measures, though essential for product requirements, are managed individually from important management factors.

-

FoodDocs’ meals security administration software program AI system permits meals companies to set up and monitor important management factors effectively, making certain compliance and security.

One of many trickiest elements of creating this plan is figuring out which operations are thought of important management factors. This course of takes a number of steps and cautious issues to meet and be certain that they’re right. On this course of, you even have to contemplate what important management factors don’t embody.

Within the meals business, there are basic operations which can be thought of as CCPs no matter their level of software in all product distribution programs from preliminary acceptance of uncooked supplies to end-product testing. These operations endure a number of screening questions to investigate if extra consideration must be centered on them or if you should set important limits for them.

Essential management factors are extra involved with making a secure product than one with the very best quality. As such, operations in regards to the visible presentation of the merchandise are sometimes disregarded from HACCP meals security applications.

Here’s a checklist of the important management level examples and operations not thought of as CCPs that will likely be mentioned on this article.

What’s a Essential Management Level (CCP)?

Essential management factors are any course of inside a meals enterprise the place parameters might be applied to forestall or eradicate any potential hazard or meals security dangers to acceptable ranges. CCPs are thought of essential management measures in retaining meals secure and making healthful meals. Additionally, they’re a part of most meals security applications.

Any meals processing facility equivalent to a meals plant, restaurant, or retail institution should determine these operations. Requirements are set to find out if they’re nonetheless throughout the restrict. Crossing these important limits considerably will increase the possibilities of inflicting foodborne sicknesses or any associated accidents.

As we have now talked about, CCPs are extra involved with meals security than the standard of the product being produced. Though not important, different operations additionally want occasional monitoring and contribute to the totality of the product, due to this fact are nonetheless a part of the meals security administration. Study extra about important management factors in-depth right here.

Essential management factors don’t embody the next operations

Operations within the meals manufacturing journey equivalent to prerequisite applications should not essentially thought of CCPs. Though vital in retaining meals secure, a few of these practices are preventive measures greater than management measures.

Essential management factors are extra involved with operations which can be thought of as a final resort to controlling or eliminating a possible hazard. Which means that there isn’t any longer any subsequent or different course of step that can eradicate the recognized potential hazard.

Beneath are a number of extra operations that important management factors don’t embody.

High quality of meals

The standard of a completed product refers back to the whole attributes of a product which can be thought of acceptable to customers. These traits embody the form, measurement, colour, texture, mouthfeel, taste, aroma, and dietary content material of the meals product. Though meals high quality is among the primary driving components that clients contemplate when shopping for and considerably impacts meals gross sales, it doesn’t contribute to the protection of the product.

Course of testing associated to high quality is extra of a priority for the standard division moderately than meals security. Completed product high quality can generally be used as an indicator for issues of safety equivalent to when discoloration happens or off-odors on account of microbiological contamination are noticed. These observations are then used for important management level willpower.

High quality of kit

The standard of kit utilized in meals manufacturing considerably impacts the end result of the merchandise. Regardless of this, they don’t seem to be a part of the CCP group. Issues and upkeep relating to the standard of kit, even when they arrive in direct contact with meals, are extra a part of prerequisite and preoperational applications than CCPs.

High quality of kit consists of correct upkeep and calibration of course of monitoring devices to make sure that uniform high quality and constant outcomes are produced.

Garnishing or visible presentation

Garnish or visible presentation is a meals preparation step that’s purely focused on the standard of offered merchandise. It’s how merchandise are embellished on a plate for serving in eating places or what the product packaging appears to be like like. Except the meals packaging supplies contribute to the retaining high quality of the product equivalent to good and lively packaging, their visible presentation doesn’t have an effect on meals security.

Customer support

This meals operation refers back to the high quality of serving the purchasers. It’s how meals handlers current themselves, talk with the purchasers, and the way they tackle any affordable chance of points which will or might not be involved with meals security.

Customer support is the eye that workers in a meals enterprise present clients with so they might really feel heard. It could additionally generally embody the sanitary situations of a processing facility. Though essential within the meals enterprise and growing annual gross sales as a complete, the breach of customer support is not going to have an effect on meals security nor can meals handlers put important limits to measure it.

Prerequisite applications (PRP)

Now, this can be a tough level. Prerequisite applications (PRP) and important management factors each contribute to sustaining meals security. Regardless of these, PRPs equivalent to Sanitation Customary Working Process and Good Manufacturing Practices are basic meals security practices and commonplace working procedures that aren’t meant to regulate any particular meals security hazard in your operations. They’re largely actions that assist management hazards equivalent to cross-contamination inside the entire course of operation.

This program consists of ample coaching, correct worker hygiene, management of worker well being situations, upkeep of unpolluted outer clothes, sanitation controls, correct meals processing facility format, clear processing plant setting, and making certain the sanitation and cleanliness of meals contact surfaces. Moreover, particular management factors equivalent to prewashing agricultural merchandise equivalent to contemporary fruits are thought of PRPs.

Prerequisite applications are a part of the fundamental meals security practices and are the strong basis used for the willpower of compliance with HACCP meals security applications.

Though these operations should not thought of as CCPs, in addition they considerably have an effect on how clients understand your meals enterprise. These operations would additionally want applicable monitoring procedures. Alternatively, high quality management points typically contribute to meals security however are nonetheless a part of the administration of a meals enterprise. These operations are generally additionally audited by any regulatory company as a part of the meals security handbook.

Essential management factors embody the next examples

Essential management factors are an integral a part of a HACCP plan within the meals chain. These operations are recognized because the final meals manufacturing course of step out there to regulate or eradicate a meals security hazard. They’re based mostly on the kind of potential hazard current in meals processing which might be a chemical hazard, bodily hazard, or organic hazard.

Their identification might generally want the assistance of a important management level resolution tree or a hazard matrix. Essential management factors are generally accompanied by a set important restrict or bodily parameter which determines the minimal and most precise values which can be nonetheless acceptable and won’t trigger any foodborne sicknesses. They’re established to forestall the lack of management of meals security.

Examples of CCPs might embody:

Cooking

The meals preparation involving the applying of warmth on uncooked supplies reduces the quantity of any remaining organic contaminants equivalent to a microbiological pathogen and makes any sort of product for distribution shelf-stable. Warmth inactivates microorganisms and makes secure meals merchandise. Cooking or the applying of thermal course of turns into a important management level for merchandise that won’t endure additional meals manufacturing course of whereas nonetheless having fascinating traits for a pathogen.

For instance, grilling beef patties, a product that’s meant to be eaten straight away, at a specific inside meals temperature ensures that the patty is suitable for eating because the pathogens have been inactivated. On this case, heating is essential to make the patties secure for consuming, making it a possible important management level. That is additionally the case for the processing of juice merchandise the place pasteurization is used to maintain the merchandise secure.

Alternatively, operations equivalent to baking the place warmth is just utilized to make a dough, a uncooked product, into an edible one by decreasing water exercise with no relation to related meals hazards can’t be thought of as CCP. Though this extends the product’s shelf life and improves consuming qualities, it doesn’t have an effect on the protection of the product. Several types of meals require completely different inside temperatures. Discover out which precise occasions fit your merchandise.

Cooling

This meals operation pertains to the fast lower of temperature of the product after it’s processed. If the cooked meals are displayed at room temperature to prepare dinner and permit them to chill down by pure means, the chance of contaminating the product considerably will increase.

Cooling is usually recommended to be accomplished throughout the first 2 to 4 hours to forestall contamination of meals and lengthen their shelf life. A really lengthy cooling course of encourages microbial development or contaminates the meals at room temperatures.

Sizzling-holding

Some meals equivalent to soups, cafeteria meals, and different meals meant to be displayed are required to be held at 140°F (60°C). This isn’t performed to simply maintain the meals heat and presentable to customers, the primary precept of hot-holding is to forestall any pathogen from rising on the meals by sustaining a comparatively excessive temperature.

If meals equivalent to these served in cafeterias are held at across the temperature hazard zone which is round 40°F to 140°F (5°C to 60°C), chances are high, microbiological contamination will happen even earlier than distribution to customers. Sizzling-holding is taken into account as a CCP since it’s the final step for some meals merchandise earlier than customers eat them.

Reheating meals

Prepared-to-eat meals equivalent to sandwiches, smoked fish, and cooked meats can generally be refrigerated to be bought for later. Earlier than consumption, these meals might must be reheated to eradicate organic hazards. Throughout this meals course of, enteric pathogens equivalent to micro organism can recuperate for the reason that meals solely got here from refrigeration and never freezing. These pathogens can get the possibility to multiply sooner and even create spores and pure toxins that can not be killed by common processing and due to this fact create hazardous meals.

When reheating meals gadgets, ensure to succeed in the inner temperature of 165°F (74°C). This consists of reheating casseroles and leftover meals.

These talked about operations are examples which can be used for a generic sort of HACCP plan. Essential management factors within the meals business are all the time accompanied by an correct document of monitoring procedures, corrective motion procedures, and correct documentation processes as necessary necessities for document retention of HACCP meals security applications.

Different important management factors can embody product formulation management and management of chemical contamination equivalent to colour additive management or adulteration with lubricants. As well as, verification actions equivalent to microbiological testing and different further testing are essential to make sure that the CCPs stay managed. Each meals processing plant and meals institution is required to have a plan that consists of those processing procedures for functions of product security.

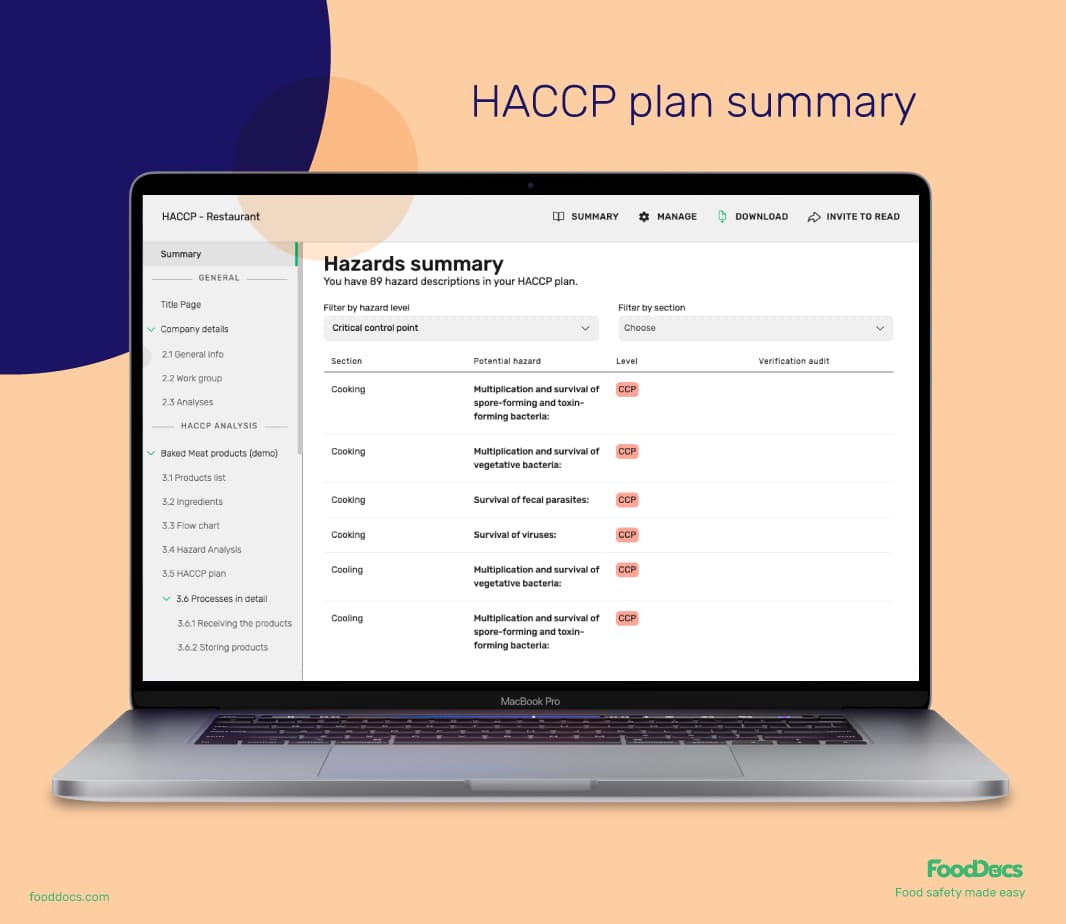

Get a Digital HACCP plan and Essential Management factors with FoodDocs

The method of figuring out which operations in a meals enterprise might be thought of as a important management level might be very arduous. Other than being very complicated, there are a number of issues wanted to be evaluated earlier than declaring an operation as a CCP within the meals business.

You should use instruments equivalent to a CCP resolution tree, hazard matrix, or exterior hyperlinks from regulatory company steerage that will help you determine CCPs together together with your course of circulate chart. Though, do not forget that important management level willpower is only one a part of making a HACCP meals security handbook and your systematic method to meals security.

HACCP plan-making takes 7 main steps and some different preparatory operations for profitable implementation throughout the meals chain. You would wish to construct a meals security staff composed of meals security consultants and representatives from different departments of your meals enterprise to make sure that all areas of your operations are coated. As a meals security supervisor, what if there’s a strategy to simplify all of those operations and end your HACCP plan in simply 1 hour?

That is precisely our method to meals security at FoodDocs. Utilizing machine-learning applications, our built-in HACCP plan builder can mechanically generate a HACCP meals security plan that’s particular on your present course of and provide help to get compliant in simply 1 hour. Our course of begins by asking you a number of primary questions on your operations and the character of your meals enterprise. These questions embody:

- what’s your enterprise sort?

- what uncooked supplies are used?

- what sort of meals do you promote?

- how huge is the quantity?

- what duties do you have got in your enterprise?

By answering these questions, our built-in software program mechanically creates a complete HACCP plan with all the required paperwork for HACCP compliance. Our skilled AI system developed by meals security consultants from FoodDocs generates the next digital data and paperwork:

- Established and analyzed meals security hazards and management measures on your uncooked supplies and operations.

- Established important management factors and corresponding important limits.

- Corrective actions, monitoring kinds, and validation actions on your operations.

- Document-keeping and documentation procedures.

- Fundamental circulate diagram of your operations.

Our system ensures a 120x sooner course of than searching for skilled recommendation from a meals security advisor that will help you make your HACCP plan for compliance. You possibly can skip utilizing a really complicated resolution tree as we determine all hazards for you. We perceive how some meals firms have particular operations which can be distinctive from different enterprise entities.

To let you enhance your digital HACCP plan previous to implementation, you’ll be able to customise and edit any part for any relevant provisions or vital enhancements. Tackle any aggressive hardship when it comes to meals security and create a big benefit by permitting us that will help you get HACCP compliant.

Obtain assurance of compliance very quickly with our built-in HACCP plan builder and minimize all of the conferences and revisions you’re sure to undergo when you select to make use of the normal methodology. Spend extra time with the efficient implementation of your HACCP plan and managing your meals enterprise with on a regular basis it can save you once you be part of us at FoodDocs.